For many U.S. companies, PCBA fabrication is often evaluated only at the manufacturing stage—SMT capability, inspection equipment, and test coverage. However, many quality and reliability issues begin before fabrication actually starts. Low yield, excessive rework, and field failures are frequently caused by missing or insufficient DFM and DFA, not by a lack of production or inspection capability. When these fundamentals are overlooked, PCBA fabrication becomes reactive, increasing risk, cost, and long-term reliability issues.

What Are DFM and DFA in PCBA Fabrication?

Design for Manufacturability (DFM)

In the context of pcba fabrication, DFM ensures that a PCB design aligns with real manufacturing capabilities rather than ideal assumptions.

DFM typically evaluates:

-

PCB layout and pad geometry

-

Component package selection and availability

-

Tolerance stack-up and process windows

-

Compatibility with solder paste printing, reflow profiles, and inspection

From a U.S. engineering perspective, DFM answers a fundamental question:

Can this design be fabricated consistently, at scale, and with acceptable yield?

A design that ignores DFM may work in prototypes but often fails during volume production.

Design for Assembly (DFA)

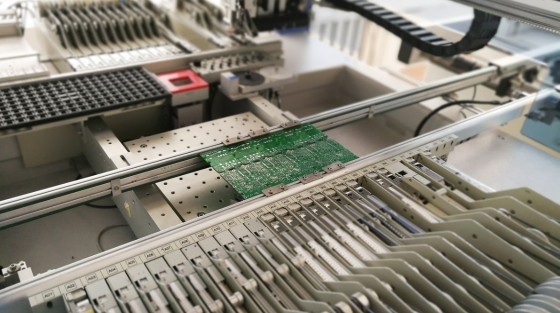

DFA focuses on how easily and reliably components can be assembled onto the PCB during PCBA fabrication.

Key DFA considerations include:

-

Component spacing and orientation

-

Package mix (BGA, QFN, fine-pitch ICs, connectors)

-

Assembly sequence and automation feasibility

-

Accessibility for soldering and inspection

While DFM addresses manufacturability at a process level, DFA addresses assembly efficiency and repeatability. Both are required for stable PCBA fabrication.

Common PCBA Fabrication Failures Caused by Poor DFM/DFA

Low Yield and High Rework Rates

One of the earliest symptoms of weak DFM/DFA is low yield during initial production runs. Common causes include:

-

Pad designs incompatible with stencil thickness

-

Component spacing that exceeds placement accuracy limits

-

Mixed package designs without proper process margin

As a result, manufacturers rely heavily on manual rework, increasing labor cost and reducing throughput—two critical concerns for U.S. sourcing teams.

Soldering Defects AOI Cannot Prevent

AOI is effective at detecting visible defects, but it cannot prevent:

-

Head-in-pillow defects in BGA packages

-

Marginal solder joints that degrade over time

-

Micro-cracks caused by thermal stress

These defects often originate from poor DFM/DFA decisions, not from assembly errors. They frequently pass inspection but fail later in the field.

Assembly Line Instability

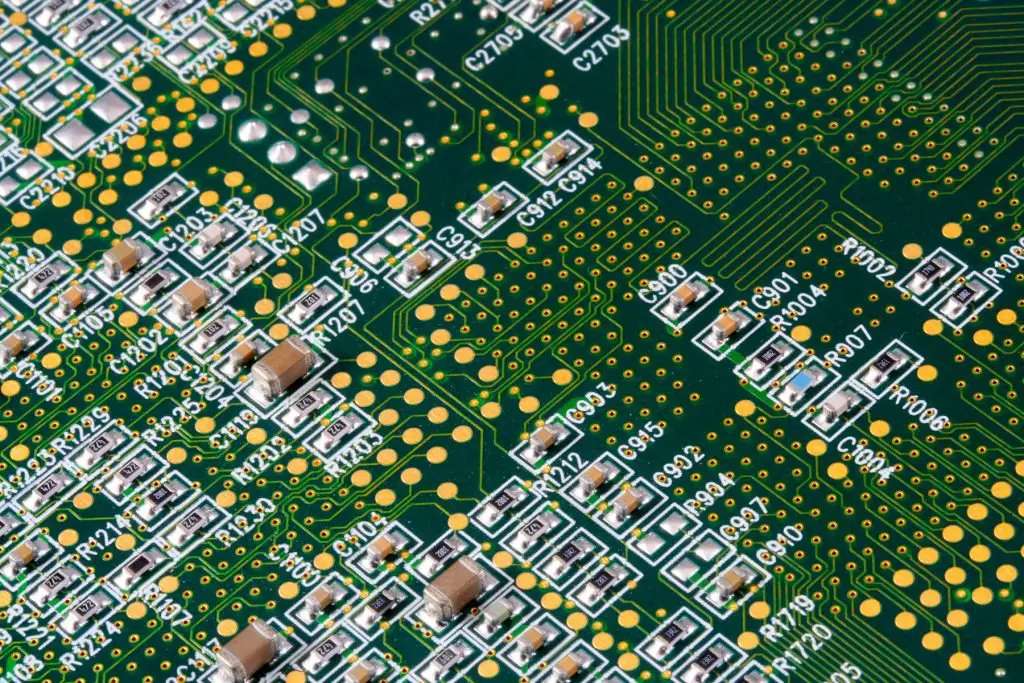

Poor DFA leads to unstable SMT lines characterized by:

-

Frequent line stoppages

-

Increased operator intervention

-

Inconsistent placement and soldering quality

This instability makes it difficult to scale PCBA fabrication from prototype to mass production.

Why AOI and Testing Cannot Fix Poor DFM/DFA

Many U.S. companies assume that advanced inspection and testing can compensate for weak design decisions. In practice, this assumption is costly.

-

AOI verifies visual correctness, not electrical or mechanical integrity

-

ICT checks connectivity but not real operating behavior

-

Functional testing identifies failures only after value has already been added

A widely accepted manufacturing principle applies:

Testing detects defects; DFM and DFA prevent them.

Relying on inspection to correct poor DFM/DFA inevitably increases scrap, rework, and total cost of ownership.

Cost Impact: How Poor DFM/DFA Increases Total Cost of Ownership

U.S. buyers evaluate PCBA fabrication through the lens of total cost of ownership (TCO), not unit price alone.

Hidden costs caused by weak DFM/DFA include:

-

Engineering time spent debugging production issues

-

Rework and scrap during ramp-up

-

Delayed product launches and lost market opportunities

-

Warranty claims and field returns

A design optimized for manufacturing may have a slightly higher initial BOM cost, but it almost always delivers lower lifecycle cost and higher reliability.

DFM/DFA for Control Boards and Industrial PCBA Fabrication

Control boards and industrial electronics place stricter demands on PCBA fabrication:

-

Higher power density

-

Mixed-signal designs

-

Continuous operation and harsh environments

In these applications, consumer-level DFM/DFA practices are insufficient. U.S. companies expect:

-

Conservative design margins

-

Robust solder joint reliability

-

Thermal and mechanical stability over long lifecycles

For industrial PCBA fabrication, DFM/DFA directly affects uptime, safety, and regulatory compliance.

What Proper DFM/DFA Looks Like in a Reliable PCBA Fabrication Partner

A reliable PCBA fabrication partner does not treat DFM/DFA as a checklist. Instead, it implements a structured, system-level approach, including:

-

Early-stage DFM/DFA review before production

-

Cross-functional input from manufacturing, quality, and test engineering

-

Clear feedback loops between design and fabrication

-

Documented recommendations and revision traceability

This level of process maturity is a key indicator U.S. OEMs use when evaluating suppliers.

When Should DFM/DFA Be Applied in the PCBA Fabrication Process?

DFM/DFA should be applied throughout the product lifecycle, especially during:

-

New Product Introduction (NPI)

-

Prototype-to-production transitions

-

Design revisions and ECOs

-

Component substitutions or supplier changes

Early application reduces risk, shortens time to market, and stabilizes PCBA fabrication outcomes.

PCBA Fabrication at SHDC: A System-Level DFM/DFA Approach

At SHDC, DFM and DFA are integrated into the PCBA fabrication process rather than treated as optional services.

SHDC’s approach typically includes:

-

Structured DFM/DFA review aligned with manufacturing capability

-

Collaboration between design, manufacturing, and quality teams

-

Electrical and functional testing strategies matched to product complexity

-

Clear documentation, traceability, and continuous feedback

This methodology is particularly valuable for:

-

Control boards for office equipment

-

Industrial and commercial electronics

-

Export-oriented PCBA fabrication projects

By aligning design intent with manufacturing reality, SHDC helps customers reduce field failures, stabilize production, and control long-term costs.

Final Thoughts: DFM and DFA Are Not Optional in PCBA Fabrication

Many PCBA fabrication failures are not caused by poor assembly or inadequate inspection. They are caused by design decisions that ignore manufacturing constraints.

For U.S. companies, DFM and DFA are essential tools for managing risk, ensuring reliability, and achieving scalable production. Successful PCBA fabrication depends on how well design, manufacturing, and quality systems are integrated from the very beginning.

FAQs – DFM/DFA in PCBA Fabrication

1. Is DFM and DFA mandatory in PCBA fabrication?

Not legally required, but considered essential best practice in modern PCBA fabrication.

2. Can AOI replace DFM/DFA in PCBA fabrication?

No. AOI finds visual defects after assembly, while DFM/DFA prevent issues before fabrication.

3. Can PCBA fabrication succeed with DFM but without DFA?

Unlikely. Without DFA, assembly stability and scalability are difficult to achieve.

4. When should DFM/DFA be applied?

During NPI, before mass production, and whenever design or component changes occur.

5. Does DFM/DFA increase PCBA fabrication cost?

Slightly at BOM level, but significantly reduces total cost by preventing rework and failures.

6. Is DFM/DFA needed for prototype or low-volume PCBA fabrication?

Yes. Early DFM/DFA reduces risk when scaling to mass production.

7. How is DFM/DFA different for industrial PCBA fabrication?

Industrial PCBA requires stricter design margins and higher long-term reliability.

8. What should a PCBA fabrication partner do for DFM/DFA?

Provide structured design reviews aligned with real manufacturing capability.

9. How does SHDC support DFM/DFA in PCBA fabrication?

SHDC integrates DFM/DFA into design review, production planning, and risk-based testing.

Tiếng Việt

Tiếng Việt 日本語

日本語