In modern electronics manufacturing, the SMT line process forms the backbone of surface mount production. While component placement and soldering are critical steps, overall product quality, yield, and scalability are largely determined by how the SMT production line is designed, controlled, and operated.

For US-based OEMs and product teams outsourcing electronics manufacturing, understanding the SMT line process is essential. Many PCBA quality issues originate not from component selection, but from line imbalance, poor process control, or insufficient inspection within the SMT line itself.

This article explains how an SMT production line works, breaks down each stage of the SMT line process, and highlights what manufacturers and buyers should evaluate when selecting an SMT partner.

What Is the SMT Line Process?

The SMT line process refers to the structured sequence of machines, operators, and inspection systems used to assemble surface-mount components onto printed circuit boards within an SMT production line.

Unlike a general discussion of SMT assembly or SMT PCBA processes, the SMT line process focuses specifically on:

-

Production line layout

-

Equipment integration

-

Inline inspection and feedback

-

Process stability and throughput

In practice, an SMT line is a coordinated system where each machine impacts downstream quality and efficiency.

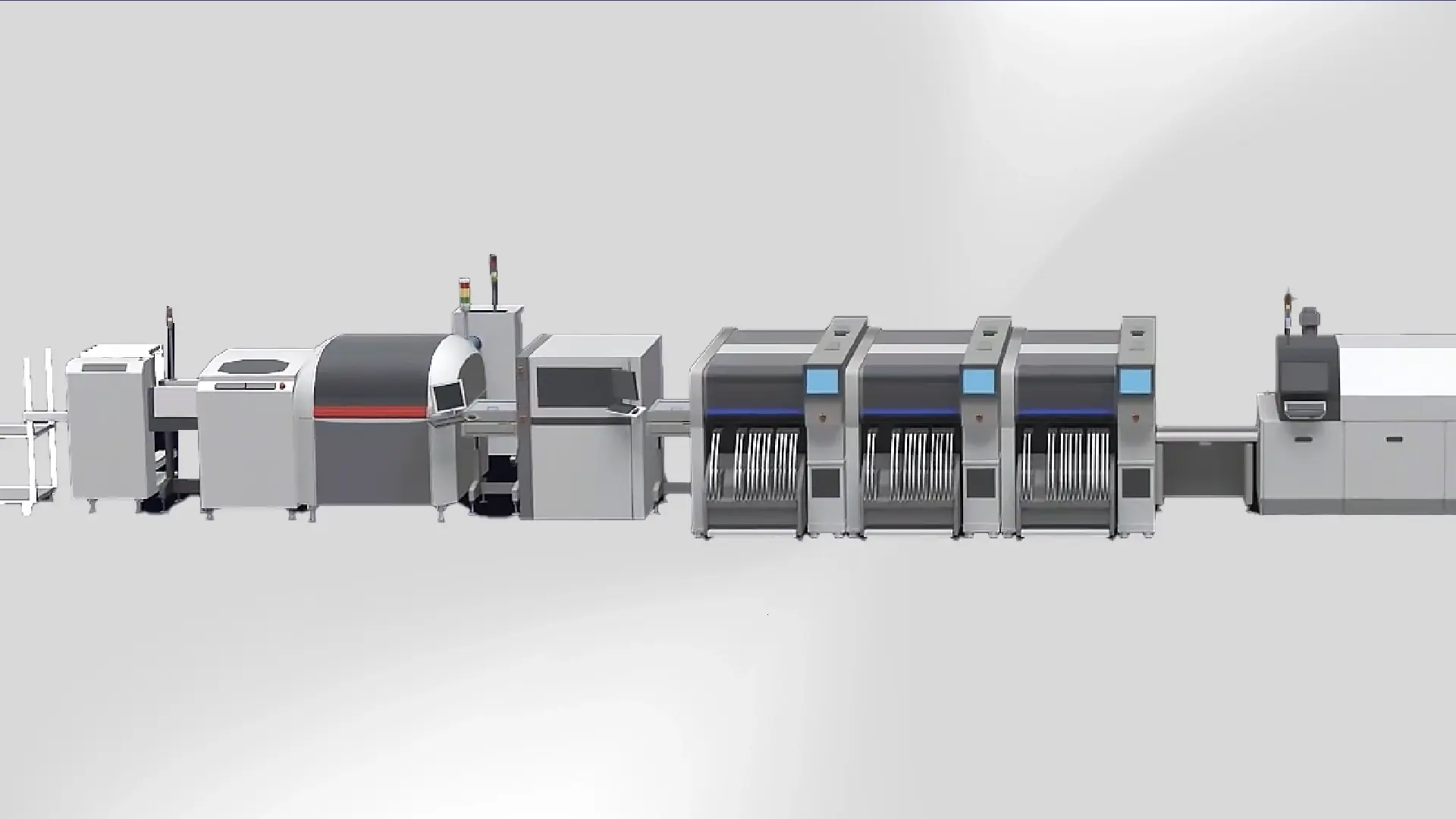

Typical Layout of an SMT Production Line

A standard SMT production line follows a linear or U-shaped layout designed to optimize material flow and minimize handling.

A typical SMT line layout includes:

-

Solder paste printer

-

SPI (Solder Paste Inspection)

-

Pick-and-place machines

-

Reflow oven

-

AOI (Automated Optical Inspection)

For high-mix environments, multiple SMT lines may be configured to support rapid changeover, while high-volume production favors dedicated, balanced lines optimized for throughput.

Line layout decisions directly affect yield, defect detection speed, and overall equipment effectiveness (OEE).

>>>Read more: SMT department process: Managing SMT lines, people, and quality control

Step-by-Step SMT Line Process

Solder Paste Printer

The SMT line process begins with solder paste printing. An automated printer applies solder paste onto PCB pads using a precision stencil.

This step is critical because solder paste volume and alignment determine solder joint quality later in the process. Poor printing often leads to defects that cannot be fully corrected downstream.

Key control factors include:

-

Stencil design and thickness

-

Print pressure and speed

-

Board alignment accuracy

SPI (Solder Paste Inspection)

SPI systems inspect solder paste deposits immediately after printing. As an inline quality gate, SPI detects insufficient paste, excess paste, or misalignment before components are placed.

US OEMs increasingly expect SPI to be part of a modern SMT line process, as early defect detection significantly improves yield and reduces rework costs.

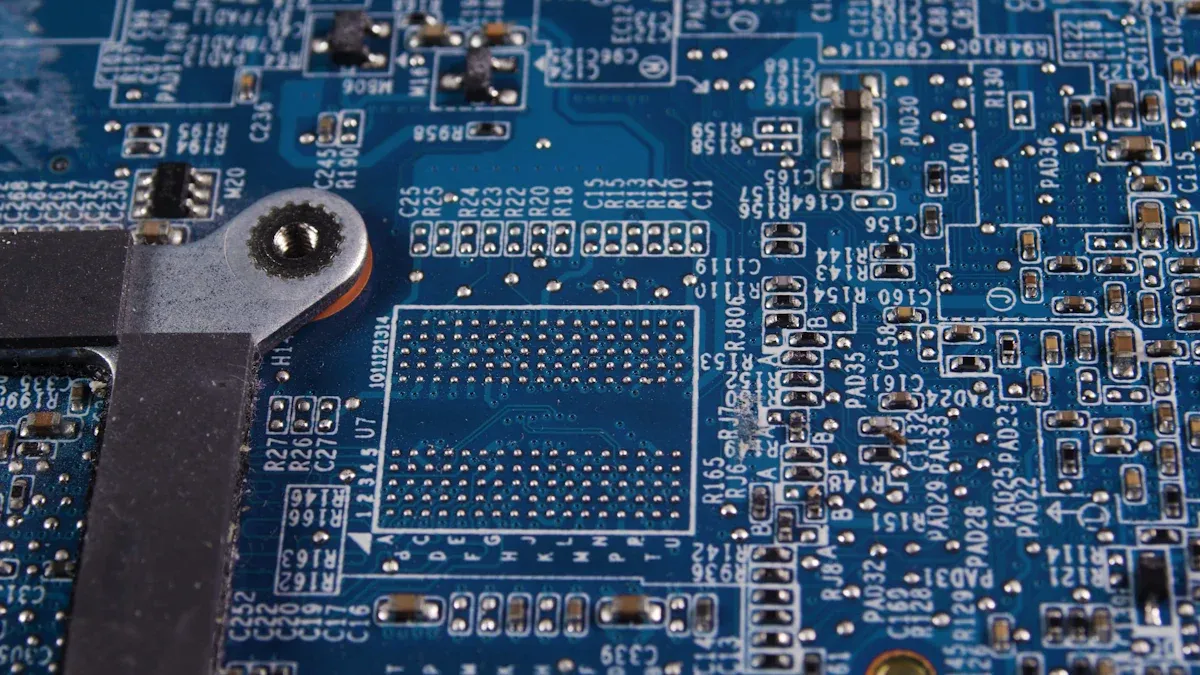

Pick-and-Place Machines

Pick-and-place machines form the core of the SMT production line. These machines place surface-mount components onto the solder-pasted PCB with high speed and precision.

In a typical SMT line process:

-

High-speed machines handle small passive components

-

High-accuracy machines place ICs, BGAs, and fine-pitch parts

Proper feeder setup, component verification, and placement accuracy are essential to prevent misplacement and polarity errors.

Reflow Oven

After component placement, boards pass through a reflow oven where solder paste melts and solidifies, forming permanent electrical and mechanical connections.

Reflow profile control is a critical element of the SMT line process. Temperature stability and zone control help:

-

Prevent solder bridging and tombstoning

-

Protect temperature-sensitive components

-

Ensure long-term solder joint reliability

A stable reflow process is often a key indicator of SMT line maturity.

AOI in the SMT Line

Automated Optical Inspection (AOI) systems inspect boards after reflow soldering. Inline AOI checks component placement, polarity, and solder joint quality.

In the SMT line process, AOI serves as a quality gate and a feedback mechanism. Inspection data can be used to adjust upstream printing or placement parameters, creating a closed-loop quality system.

Inline vs. Offline Processes in an SMT Line

SMT lines can be configured with inline or offline inspection and handling processes.

-

Inline SMT line processes maximize throughput and reduce manual handling.

-

Offline inspection offers flexibility for low-volume or prototype builds but may slow feedback.

For volume production, fully inline SMT line processes are preferred due to faster defect detection and better data integration.

Process Control in the SMT Line

A mature SMT line process relies on data-driven control rather than manual intervention. Key process control elements include:

-

Statistical Process Control (SPC)

-

Traceability by board or batch

-

Closed-loop feedback between SPI, AOI, and placement machines

These controls help maintain consistency across shifts, operators, and production lots.

>>>Read more: SMT PCBA Process Explained: From Bare PCB to Reliable Electronic Assembly

Common SMT Line Problems and How They Are Addressed

Even advanced SMT production lines face challenges, including:

-

Line imbalance between machines

-

Bottlenecks during changeover

-

Excessive false calls from AOI

-

Inconsistent material handling

Experienced manufacturers address these issues through line balancing, preventive maintenance, operator training, and continuous process optimization.

SMT Line Requirements for Prototype vs. Volume Production

The SMT line process differs significantly between prototype and mass production.

-

Prototype SMT lines emphasize flexibility, fast changeover, and engineering support.

-

Volume SMT lines prioritize stability, automation, and throughput efficiency.

Manufacturers that support both stages must design SMT lines capable of scaling without introducing quality risk.

What OEMs Should Evaluate in an SMT Line Before Outsourcing

When evaluating SMT manufacturing partners, OEMs should look beyond equipment lists and consider:

-

Line setup and balancing capability

-

Inspection coverage and data usage

-

Engineering involvement during NPI

-

Documentation and change control processes

A well-managed SMT line process often matters more than machine brand or line speed.

SMT Line Capabilities in Vietnam

Vietnam has emerged as a competitive location for SMT manufacturing, supported by skilled labor and improving production infrastructure. Many factories now operate modern SMT production lines capable of meeting international quality expectations.

For US companies seeking to diversify supply chains, Vietnam offers a practical alternative—especially when working with manufacturers that operate disciplined SMT line processes aligned with global standards.

SMT Line Services at SHDC

Executing a reliable SMT line process requires more than advanced equipment. It requires engineering alignment, process discipline, and consistent quality control.

SHDC operates modern SMT production lines designed to support international customers across prototype, NPI, and scalable production. With inline inspection systems, structured process control, and experienced engineering teams, SHDC manages each stage of the SMT line process with repeatability and transparency.

By combining Vietnam-based manufacturing advantages with a process-driven approach to SMT line management, SHDC supports US OEMs seeking reliable electronics manufacturing partners.

Final Thoughts

The SMT line process is not simply a collection of machines—it is an integrated manufacturing system. A well-designed and well-controlled SMT production line forms the foundation of consistent PCBA quality, high yield, and scalable electronics manufacturing.

For OEMs and product teams, understanding the SMT line process is essential when evaluating manufacturing partners and managing long-term production risk.

FAQs

What machines are included in an SMT line?

A typical SMT line includes a solder paste printer, SPI, pick-and-place machines, reflow oven, and AOI system.

How does the SMT line process impact PCBA quality?

Proper line setup, inspection, and process control reduce defects, improve yield, and enhance long-term reliability.

What is the difference between SMT line process and SMT assembly process?

The SMT assembly process focuses on placing and soldering components, while the SMT line process covers equipment integration, layout, inspection, and production flow.

How many operators are required for an SMT line?

The number of operators depends on automation level, line configuration, and production volume, but modern SMT lines minimize manual intervention.

Is SMT line automation important for high-volume production?

Yes. Automation improves consistency, throughput, and data-driven quality control in high-volume SMT manufacturing.

Tiếng Việt

Tiếng Việt 日本語

日本語