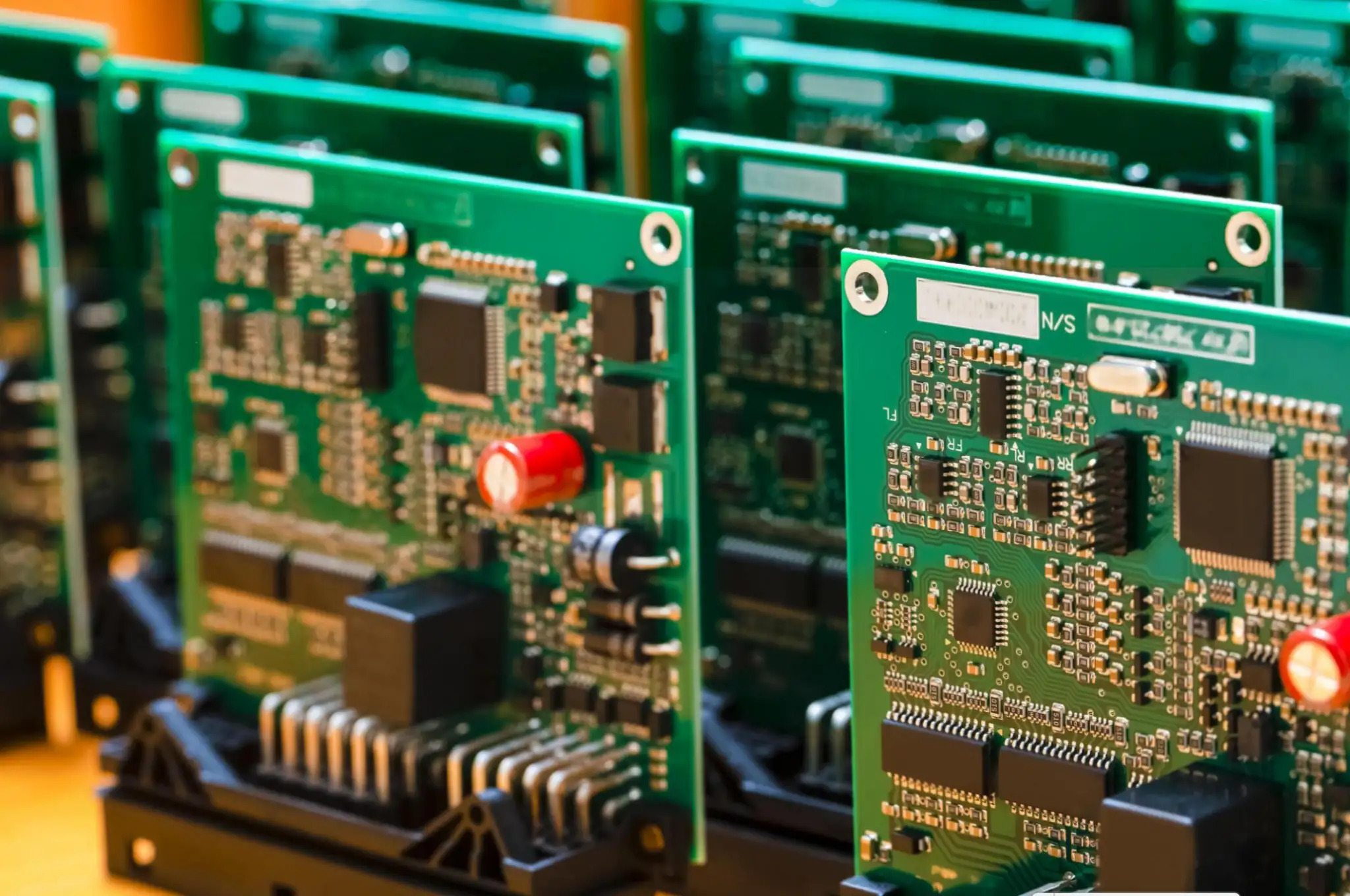

In early-stage hardware development, the first working board is a critical milestone. A well-executed Prototype PCBA helps validate product concepts, speed up engineering decisions, and reduce downstream manufacturing risk. For U.S. companies, Prototype PCBA manufacturing is not just a smaller version of mass production. It is a distinct phase with different priorities, where early decisions directly impact product reliability, timelines, and scalability.

What Is Prototype PCBA Manufacturing?

Prototype PCB assembly refers to the process of assembling printed circuit boards in small quantities—typically from one to several dozen units—during the research, development, or new product introduction (NPI) stage.

Unlike production assembly, which focuses on scalability, cost optimization, and throughput, early-stage builds are primarily about design validation. This phase helps engineering teams answer critical questions such as:

-

Does the circuit operate as intended?

-

Are component footprints and land patterns correct?

-

Does the layout support stable power delivery, signal integrity, and thermal performance?

-

Are there manufacturability concerns that could affect future scaling?

This type of assembly is commonly used by startups, R&D teams, and engineering-led organizations that require fast technical feedback before committing to volume production.

>>>Read more: What Is PCBA Manufacturing and How Does It Work?

Prototype PCBA vs Production PCBA: Key Differences

While both involve PCB assembly, early-stage builds and full-scale production differ in several important ways.

Prototype-focused assembly prioritizes speed, flexibility, and engineering insight. Lead times are often compressed, component sourcing may require substitutions, and manual or semi-automated processes are common. Close engineering support and frequent communication are essential.

Production assembly, by contrast, emphasizes process stability, repeatability, and cost control. Automation levels are higher, acceptance criteria are tightly defined, and the focus shifts toward long-term yield and reliability at scale.

Applying production assumptions to a prototype build—or treating early validation like mass production—is a common mistake that increases risk rather than reducing it.

Typical Prototype PCBA Manufacturing Process

Although simplified, early-stage PCB assembly still follows a structured process designed to uncover issues as early as possible.

Design Review and Data Readiness

Successful builds begin with complete and accurate design data, including Gerber files, a bill of materials (BOM), pick-and-place data, and assembly drawings. Early design review helps identify footprint errors, polarity risks, and spacing issues before assembly starts.

Even at this stage, basic manufacturability checks can prevent expensive rework later.

Material Sourcing for Prototypes

Component availability is one of the most common challenges during early builds. Engineers often specify parts without fully considering lead times or approved alternates. Assembly partners must balance design intent with practical sourcing, sometimes recommending functionally equivalent components to maintain schedule.

Clear agreement on substitution rules is critical.

Assembly and Soldering

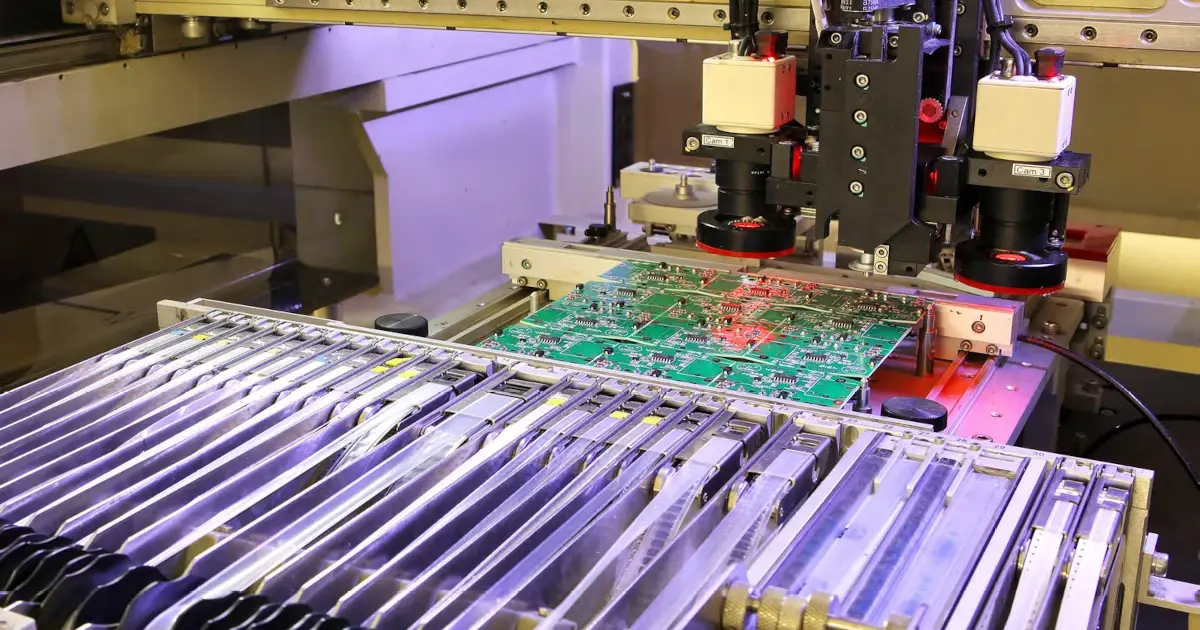

Early-stage assembly typically combines automated SMT placement with manual operations, especially for fine-pitch, odd-form, or low-quantity components. The goal is not maximum throughput, but precision and adaptability.

Process decisions made here can significantly influence how smoothly the design transitions into volume manufacturing.

Inspection and Prototype-Level Testing

Visual inspection and AOI are widely used, but they are not sufficient on their own. AOI detects solder and placement defects, but cannot verify electrical functionality.

Basic electrical checks or functional testing—when available—add meaningful validation during early builds.

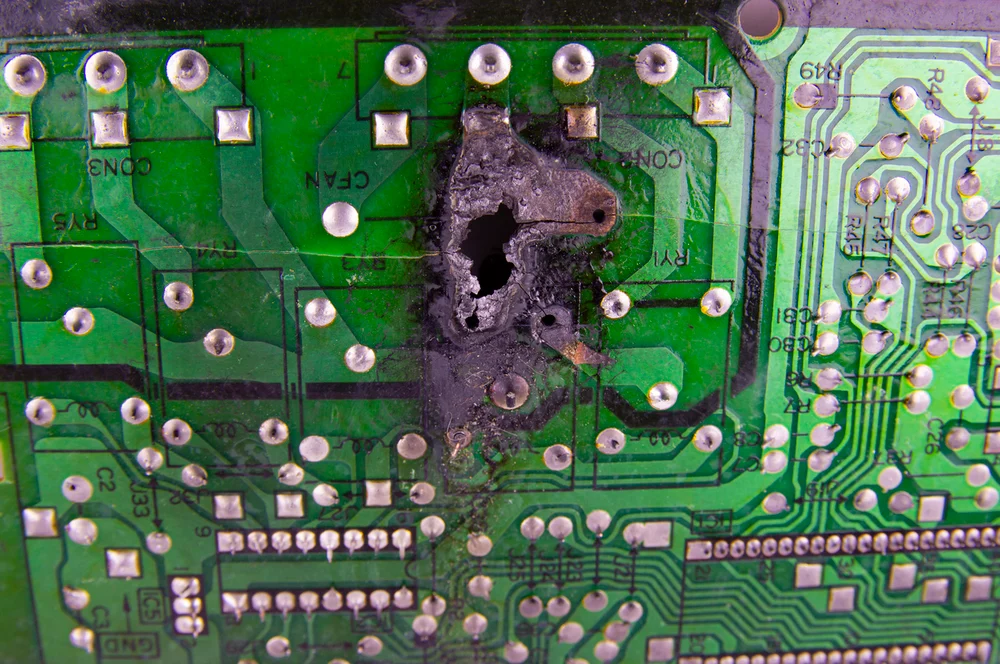

Common Failures in Early PCB Assembly (And Why First Builds Go Wrong)

Many first-build failures are caused not by complex design flaws, but by small oversights amplified by tight schedules.

Typical issues include incorrect footprints, mismatched BOM data, missing test points, or insufficient allowance for assembly tolerances. In many cases, the lack of early manufacturability review allows these problems to surface only during assembly.

Each failure at this stage delays learning and forces additional design iterations.

Why DFM Is Especially Important in Early Builds

A common misconception is that design-for-manufacturing can be addressed later during production. In practice, manufacturability considerations are often most critical during early-stage assembly.

Early feedback helps engineers understand how design choices affect build quality, testability, and long-term reliability. Minor layout changes—such as pad geometry, component spacing, or panelization strategy—can dramatically improve first-build success.

For U.S. companies focused on time-to-market, early manufacturability review is a strategic advantage rather than an optional step.

Fast Turn Builds and Time-to-Market

Speed is a major reason companies outsource early PCB assembly. However, fast turnaround does not simply mean rushing the build.

Most delays result from incomplete data, unclear communication, or last-minute design changes. Manufacturers that integrate design review, sourcing, and assembly planning early can significantly reduce cycle time.

Parallel workflows—reviewing design files while sourcing components, for example—are often key to achieving reliable fast-turn builds.

From Prototype to Production: Planning Ahead

A successful early build does more than validate functionality—it establishes a foundation for scalable manufacturing.

Design decisions made at this stage influence future cost, yield, and reliability. Component selection, test strategy, and process assumptions should all be evaluated with volume production in mind.

Companies that treat early builds as part of a continuous product lifecycle are better prepared to scale efficiently.

Why Companies Work with SHDC for Prototype PCBA Manufacturing

Proven Engineering Experience

SHDC is one of the few Vietnam-based manufacturers with early expertise in supporting prototype-stage PCB assembly for a wide range of electronic products, including printers, computers, office equipment, and consumer electronics. Founded in 2022, SHDC is led by a management and engineering team with experience from global technology corporations, bringing strong engineering discipline to early product validation.

Flexible Production Capability

SHDC supports low-volume builds across a wide range of board sizes and component complexities. Capabilities span from compact 50 × 50 mm boards to large-format assemblies up to 460 × 550 mm, with support for components ranging from ultra-small 0201 packages to large components up to 100 mm. Flexible FPC assembly further enables support for advanced electronic applications.

Experience Supporting Global Markets

Beyond board-level assembly, SHDC is among a limited number of manufacturers in Vietnam capable of delivering complete electronic products for export. The company has participated in the production of PlugBug chargers distributed through Apple retail channels in the U.S. and Europe, as well as computer peripherals for leading global brands. This experience supports customers targeting international markets and long-term scalability.

>>>Read more: Profile’s SHDC Company

FAQs

What is the typical lead time for prototype PCBA?

Lead times vary, but many prototype PCBA builds are completed within 5–10 business days, depending on design readiness and component availability.

How many boards are usually built in a prototype run?

Prototype quantities typically range from 1 to 50 units, depending on validation needs.

Is AOI enough for prototype PCBA testing?

AOI is useful for detecting assembly defects, but functional testing is recommended whenever possible.

Can prototype PCBA manufacturers help with DFM?

Yes. In fact, early DFM support is one of the most valuable aspects of prototype PCBA manufacturing.

What files are required to start a prototype PCBA build?

At minimum: Gerber files, BOM, pick-and-place data, and assembly drawings.

How is prototype PCBA different from low-volume production?

Prototype PCBA focuses on design validation and learning, while low-volume production emphasizes repeatability and process stability.

Tiếng Việt

Tiếng Việt 日本語

日本語