For US companies and buyers developing electronic products, PCBA manufacturing is a critical step that directly impacts product quality, cost, and time to market. Whether you are a hardware startup building your first prototype or an established OEM scaling production, understanding understanding what PCBA manufacturing is helps you make better sourcing and engineering decisions.

What Is PCBA Manufacturing?

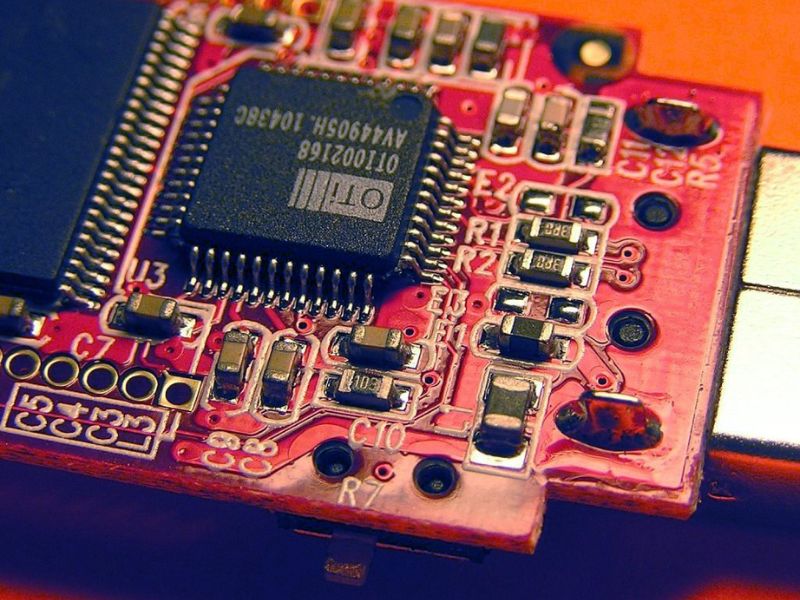

PCBA manufacturing is the process of mounting and soldering electronic components onto a printed circuit board (PCB), transforming it into a fully assembled and functional electronic module.

A completed PCBA typically includes:

- A fabricated PCB

- Surface-mount (SMT) and/or through-hole (THT) components

- Soldering and assembly processes

- Inspection and functional testing

PCBA is the final electronic assembly that can be directly integrated into end products such as industrial controllers, medical devices, IoT systems, and consumer electronics.

>>>PCBA and PCB: A detailed technical comparison of printed circuit boards and assemblies

How Does the PCBA Manufacturing Process Work?

1. PCB Fabrication

The PCBA manufacturing process begins with bare PCB fabrication, which serves as the physical foundation of the entire electronic assembly. The PCB is manufactured based on:

- Customer-provided Gerber files

- Stack-up requirements, including layer count, copper thickness, and dielectric materials

- Material specifications, such as FR-4, Rogers, or specialized materials for high-frequency and high-power applications

- PCB quality has a direct impact on signal integrity, thermal performance, and overall product lifespan, making this a foundational step in the entire PCBA manufacturing process.

2. Component Sourcing

Once the PCB is fabricated, the next step is component sourcing and management according to the Bill of Materials (BOM). This is one of the most critical stages, particularly for export-oriented projects and the US market.

This stage typically includes:

- Approved Vendor Lists (AVL) to ensure the use of genuine, authorized components

- Lead time and component lifecycle checks to avoid risks associated with end-of-life (EOL) parts

- Counterfeit and low-quality component risk management through traceability and distributor control

A professional PCBA manufacturer does more than simply procure components—they provide engineering support and sourcing consultation to optimize cost, availability, and supply chain reliability.

3. SMT Assembly (Surface Mount Technology)

SMT assembly is the primary process used in most modern PCBA production lines. At this stage:

- Surface-mount components are accurately placed onto the PCB using automated pick-and-place machines

- The PCB then passes through a reflow soldering oven, where solder paste melts and forms both electrical and mechanical connections between components and solder pads

SMT enables high component density, precise placement, and stable high-volume production, making it particularly suitable for products such as IoT devices, consumer electronics, industrial equipment, and medical electronics.

4. Through-Hole Assembly (THT – Through-Hole Technology)

Certain components still require through-hole assembly (THT), especially those that:

- Require high mechanical strength

- Handle high current or high voltage

- Must operate in environments with vibration or extreme temperatures

THT components are inserted through plated holes in the PCB and soldered using:

- Wave soldering

- Or selective soldering for more complex or mixed-technology designs

Many PCBA projects today involve hybrid SMT + THT assemblies, which demand flexible manufacturing capabilities and strict process control.

What Is Included in PCBA Manufacturing Services?

PCBA manufacturing services can be provided as partial assembly services or as full turnkey solutions, depending on the project scope and customer requirements.

A typical PCBA manufacturing service includes:

- PCB fabrication coordination, based on customer design files and specifications

- Component sourcing and procurement according to the Bill of Materials (BOM)

- SMT and THT assembly using automated production lines

- Soldering and board cleaning to ensure reliable electrical connections

- Electrical inspection and functional testing

- Final inspection, packaging, and shipment preparation

Turnkey PCBA manufacturing covers the entire process—from BOM sourcing and component procurement to assembly, testing, and delivery of fully tested PCBAs. This approach is commonly preferred by US startups and OEMs because it helps simplify supply chain management, reduce sourcing risk, and shorten time to market.

What Factors Affect PCBA Manufacturing Cost?

PCBA manufacturing cost depends on multiple factors, including:

- Board complexity and PCB layer count

- Number and types of components

- SMT versus THT assembly ratio

- Production volume (prototype vs. mass production)

- Testing and quality requirements

US buyers often compare domestic and offshore PCBA manufacturing to balance cost and responsiveness. Offshore PCBA manufacturing—particularly in Vietnam—can offer significant cost advantages while maintaining reliable production capability.

How Long Does PCBA Manufacturing Take?

Typical lead times vary by project type:

- Prototype PCBA: 7–15 working days

- Low-volume production: 2–4 weeks

- Mass production: 4–8 weeks

Early design review and clear documentation can significantly reduce PCBA manufacturing lead time.

How to Choose a PCBA Manufacturing Partner?

When evaluating a PCBA manufacturing partner, US companies typically consider:

- Compliance with IPC and ISO standards

- Engineering and DFM support capability

- Experience in relevant industries

- Quality control and traceability systems

- Communication and project management efficiency

A transparent manufacturing process and proactive engineering feedback are often more important than lowest price alone.

Where Is PCBA Manufacturing Commonly Done Today?

PCBA manufacturing is commonly located in:

- United States: High mix, low volume, regulated industries

- China: High volume, cost-driven production

- Southeast Asia (including Vietnam): Growing alternative with improving technical depth.

SHDC – Leading PCBA Manufacturer in Vietnam

SHDC is a member company of the NAHACO Group, headquartered in Hai Duong Province, Vietnam. The company is among a limited number of Vietnamese enterprises that pioneered printed circuit board assembly (PCBA) manufacturing for a wide range of products, including printers, fax machines, computers, electronic equipment, and home appliances.

SHDC is supported by a highly experienced management and engineering team, many of whom have previously held senior positions at major global corporations. With a strong technical foundation and continuous investment in manufacturing capabilities, SHDC is steadily working toward becoming one of Vietnam’s leading companies in PCB and PCBA assembly.

In terms of production capability, SHDC can manufacture and assemble various types of circuit boards, ranging from small PCB sizes of 50 × 50 mm to large-format boards up to 460 × 550 mm. The company is capable of assembling components from ultra-small packages such as 0201, 0402, and 0603 to large components up to 100 mm in size. In addition, SHDC has the capability to produce flexible printed circuits (FPCs) for high-technology products such as smartphones and advanced electronic devices.

Main Products

- PCBA for printers and office equipment

- PCBA for desktop computers, laptops, and USB devices

- PCBA for home appliances

- Other custom electronic circuit boards

Beyond providing OEM and ODM manufacturing services, SHDC also owns its own consumer electronics brand, Winsler, with the goal of bringing high-quality electronic products bearing a Vietnamese brand—designed and manufactured in Vietnam—to both domestic and international markets.

Notably, through its collaboration with Twelve South on the PlugBug project, SHDC achieved a significant milestone by delivering Vietnam-manufactured technology products to the global market, meeting Apple’s stringent quality and compliance standards. This achievement not only demonstrates SHDC’s competitive manufacturing capabilities, but also contributes to elevating Vietnam’s position in the global electronics manufacturing industry.

Final Thoughts

PCBA manufacturing is a core capability in modern electronics production. For US buyers, a clear understanding of the manufacturing process, cost drivers, and supplier selection criteria is essential to building reliable and scalable products.

Choosing the right PCBA manufacturing partner is not merely a sourcing decision—it is a strategic step toward long-term product success.

Tiếng Việt

Tiếng Việt 日本語

日本語