PCBA and PCB are closely related but not the same. PCB is the bare circuit board, while PCBA is the assembled board with electronic components installed. Understanding this difference is essential for accurate cost estimation, production planning, and reliable electronics manufacturing.

What is a PCB?

A PCB (Printed Circuit Board) is a bare circuit board that mechanically supports and electrically connects electronic components using conductive copper traces. At this stage, no components are installed, so a PCB by itself cannot function as an electronic product.

PCBs are typically made from materials such as FR-4, aluminum, or high-frequency laminates, depending on the application. They can be single-layer, double-layer, or multilayer, with increased layer count allowing for higher circuit density and more complex designs.

The PCB manufacturing process focuses on fabrication only, including board layout, copper etching, drilling, plating, and surface finishing. PCBs serve as the foundation for PCBA, providing the physical and electrical platform required for assembly and final product performance.

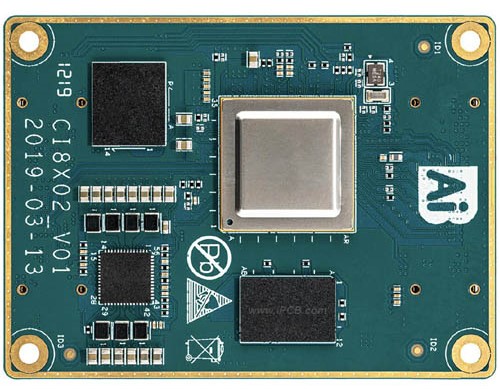

What is PCBA?

A PCBA (Printed Circuit Board Assembly) is a fully assembled PCB with electronic components such as ICs, resistors, capacitors, and connectors mounted and soldered onto the board. Unlike a bare PCB, a PCBA is electrically functional and ready to be integrated into an end product.

PCBA assembly typically involves SMT (Surface Mount Technology), through-hole assembly (THT/DIP), or a combination of both. After assembly, each board undergoes inspection and testing, including AOI, X-ray inspection, and functional testing, to ensure performance, reliability, and compliance with industry standards.

In electronics manufacturing, PCBA represents the final and most critical stage, directly determining product quality, yield, and long-term reliability.

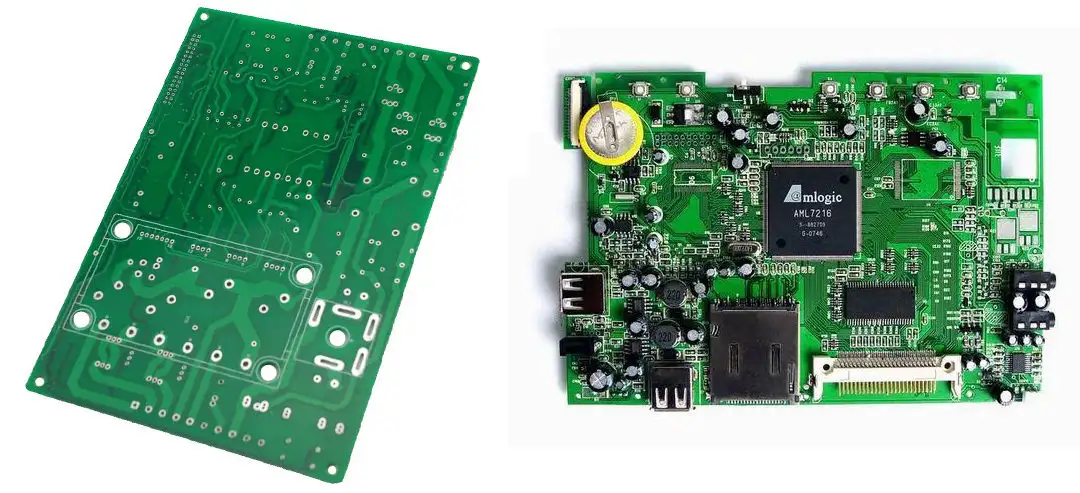

PCBA and PCB: Core differences you need to understand

Although PCBA and PCB are closely connected within the electronics manufacturing chain, they fundamentally represent two distinct stages of production, with clear differences in functionality, manufacturing scope, and cost structure.

Functionality

A PCB is a bare board that provides mechanical support and electrical interconnections, but cannot operate on its own. In contrast, a PCBA is a fully assembled circuit board, where electronic components are mounted, soldered, and verified, enabling the board to perform its intended electrical functions.

Manufacturing stage

PCB fabrication belongs to the early stage of electronics manufacturing, focusing on circuit layout, materials, and geometric precision. PCBA takes place at the final stage, where the PCB is populated with components, soldered, inspected, and functionally tested, making it ready for integration into a complete system or end product.

Cost structure

PCB costs are primarily driven by base materials, layer count, and fabrication complexity, resulting in relatively predictable and lower pricing. PCBA costs, however, include component sourcing, assembly processes (SMT/THT), labor, quality inspection, and functional testing, leading to higher overall costs that scale with product complexity.

A clear understanding of these core differences helps engineers and sourcing teams avoid miscommunication during supplier selection, RFQ preparation, and quotation evaluation, ultimately improving manufacturing efficiency and technical risk control.

PCB vs PCBA

| Criteria | PCB | PCBA |

|---|---|---|

| Components | Not installed | Fully installed |

| Functionality | Non-functional | Fully functional |

| Manufacturing stage | Fabrication stage | Final assembly stage |

| Cost | Lower | Higher (assembly & testing included) |

| Typical use | Base board | Ready for integration |

When do you only need PCB fabrication?

Ordering bare PCB fabrication—without component assembly—is appropriate when assembly, validation, or iteration is managed internally, or when the project has not yet reached a production-ready stage.

In practice, PCB-only manufacturing is suitable in the following scenarios:

In-house assembly capability

Engineering teams with internal SMT tools, manual soldering stations, or pilot assembly lines may only require bare PCBs as the physical and electrical foundation for subsequent assembly and testing.

Early-stage R&D and engineering validation

During research, proof-of-concept, or design verification phases, circuit designs often change frequently. Using bare PCBs allows engineers to iterate layouts, evaluate alternative components, and debug circuits without incurring repeated assembly costs.

Prototyping, electrical testing, or mechanical evaluation

Bare PCBs are commonly used for signal integrity analysis, EMI/EMC pre-compliance checks, thermal evaluation, or mechanical fit validation, where full functional assembly is not yet required.

Cost and risk control in early development

At the initial stages of a project, limiting scope to PCB fabrication helps reduce financial exposure before the design is frozen and ready for scale-up.

As a result, bare PCBs are most frequently used by design engineers, R&D teams, and technology startups that maintain control over assembly and accept a higher degree of experimentation.

When Do You Need a Full PCBA Service?

A full PCBA service—covering component sourcing, assembly, inspection, and functional testing—is recommended once a product moves beyond prototyping and requires repeatability, reliability, and scalable production.

Full PCBA manufacturing becomes essential under the following conditions:

Medium- to high-volume production

As production volume increases, consistency across assemblies becomes critical. Controlled PCBA processes minimize variation and improve manufacturing yield compared to manual or semi-automated assembly.

High reliability and performance requirements

Applications in industrial control, power electronics, automotive, or medical devices demand stable solder joints, precise component placement, and compliance with IPC standards—requirements best met through professional PCBA lines.

Strict quality control and functional testing

Advanced inspection methods such as AOI, X-ray, ICT, and functional testing are difficult to implement effectively without dedicated infrastructure and process discipline.

Time-to-market pressure

Outsourcing PCBA allows engineering teams to focus on product development while manufacturing, procurement, and testing are handled in parallel, significantly reducing overall product launch timelines.

Cost Factors in PCB and PCBA Manufacturin

PCB Cost Driver

- Number of layers

- Board size and design complexity

- Material selection

- Surface finis

PCBA Cost Drivers

- Bill of Materials (BOM)

- Assembly technology (SMT / THT)

- Inspection and testing requirement

- Production volume and manufacturing yield

>>> What Is PCBA Manufacturing and How Does It Work?

What Are the Key Requirements for PCB and PCBA Manufacturing for the US Market?

For the US market, PCB and PCBA manufacturers must comply with strict technical standards, regulatory requirements, and quality expectations. Specifically, manufacturers are required to meet the following criteria:

- Compliance with IPC standards, which define workmanship, materials, assembly quality, and long-term reliability

- Adherence to UL, RoHS, and REACH regulations, ensuring electrical safety and environmental compliance

- High requirements for product quality and technical documentation, including material traceability, inspection records, and comprehensive test reports

- Meeting these requirements is essential for ensuring product acceptance, regulatory approval, and long-term success in the US electronics market.

SHDC: A Trusted PCB and PCBA Manufacturing Partner for the US Market

Due to the stringent requirements of the US market, selecting a manufacturing partner with proven experience serving US customers is critically important. SHDC is one of the PCB and PCBA manufacturers in Vietnam that fully complies with IPC standards and UL/RoHS/REACH requirements, while maintaining a robust quality management system and complete technical documentation aligned with US customer expectations.

Notably, SHDC plays a strategic manufacturing role in the production of Apple’s PlugBug, ensuring compliance with Apple’s international quality, safety, and reliability standards. Through its collaboration with Twelve South on the PlugBug project, SHDC has marked an important milestone by delivering Vietnam-manufactured technology products to the global market while meeting Apple’s stringent requirements. Additionally, SHDC has received strong recognition from Japanese technical experts for its manufacturing quality, process control, and consistency.

Conclusion

Understanding the differences between PCB and PCBA helps engineers and businesses choose the right manufacturing approach for each project. While PCBs are suitable for early-stage development, PCBAs are essential for scalable, reliable, and production-ready electronics. Selecting the right solution reduces technical risk and improves overall manufacturing efficiency.

Tiếng Việt

Tiếng Việt 日本語

日本語