In PCBA manufacturing, AOI (Automated Optical Inspection) is often treated as a key quality checkpoint. However, many US companies are discovering that passing AOI alone does not guarantee reliable products. PCBA testing is not just about visual inspection—it is about verifying electrical performance, functional behavior, and long-term reliability. This article explores whether AOI is enough in PCBA testing and what US buyers really look for to prevent field failures and quality risks.

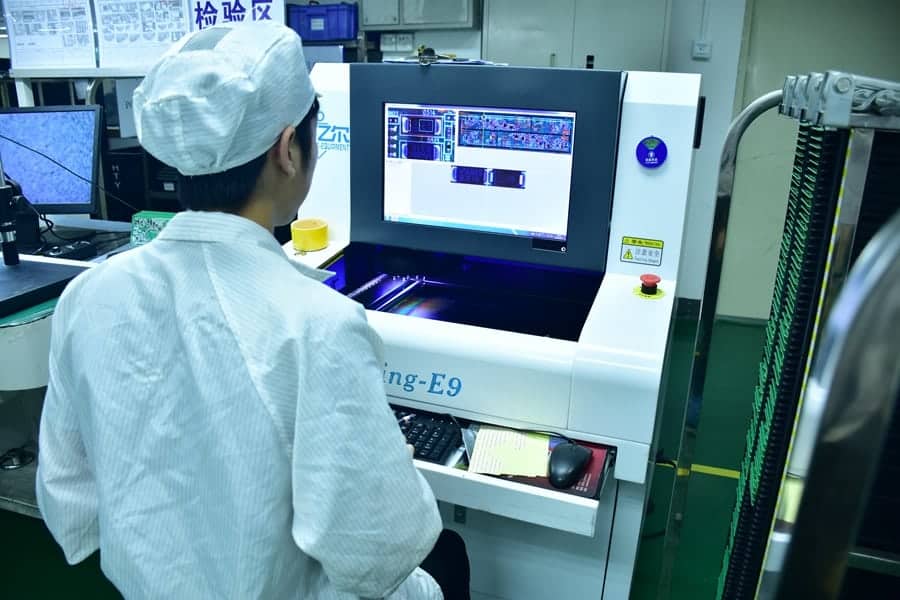

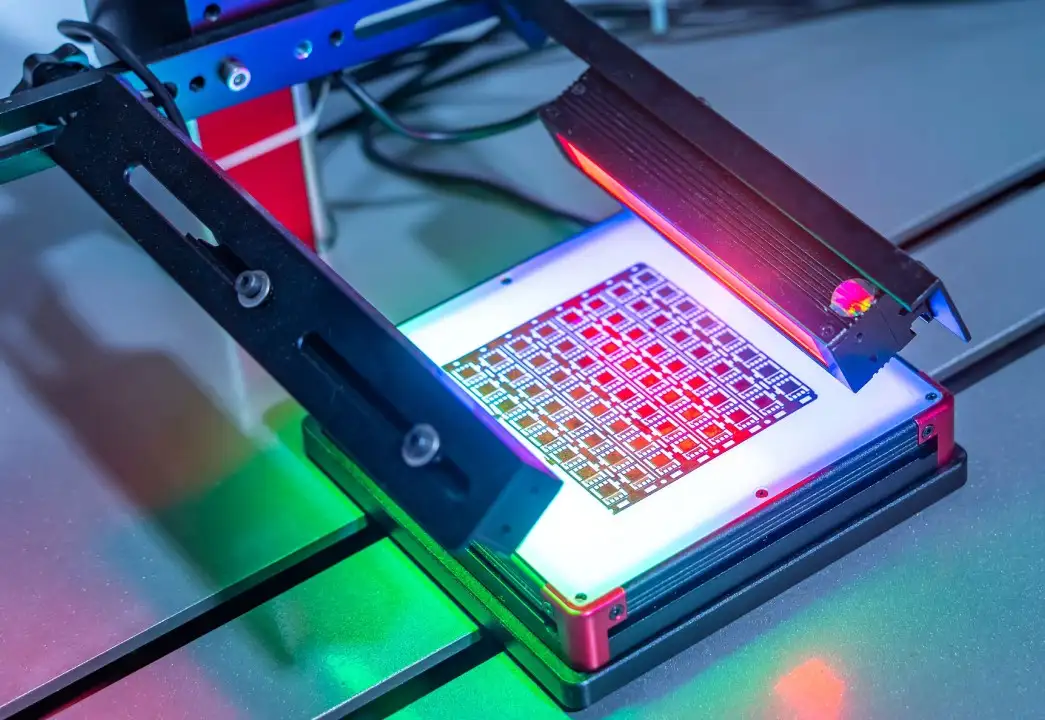

What Is AOI in PCBA Testing?

AOI (Automated Optical Inspection) is a vision-based inspection method used to identify visible defects on assembled printed circuit boards.

Typically applied after SMT placement and reflow soldering, AOI systems use cameras and image recognition to compare assembled boards against reference models.

AOI is commonly used to detect:

-

Missing or misaligned components

-

Incorrect polarity or orientation

-

Solder bridges

-

Visually insufficient or excessive solder

Because AOI is automated, fast, and repeatable, it has become a baseline expectation in modern PCBA manufacturing—especially for US buyers sourcing offshore.

However, AOI inspects what the board looks like, not how it behaves electrically or mechanically over time.

What AOI Can Detect — and What It Cannot

Defects AOI Is Effective At Catching

AOI performs well when identifying:

-

Clear placement errors

-

Orientation and polarity issues

-

Obvious soldering defects visible on the surface

These issues are critical to catch early, and AOI dramatically reduces dependence on manual inspection.

Defects AOI Cannot Reliably Detect

AOI cannot evaluate:

-

Electrical continuity and signal integrity

-

Mechanical strength of solder joints

-

Thermal sensitivity of components

-

Latent defects that develop after deployment

For example:

-

A solder joint may visually pass AOI but fail after thermal cycling

-

A component may be correctly placed but electrically degraded

-

A control board may function during initial testing but fail under real load conditions

This is where many real-world failures originate.

Why Passing AOI Is Not Enough in PCBA Testing

From the perspective of US companies, AOI addresses assembly correctness, not functional reliability.

AOI cannot answer critical questions such as:

-

Does the board operate correctly across voltage, temperature, and load ranges?

-

Will the board remain stable after months or years in the field?

-

Are there marginal conditions that only appear during extended operation?

This explains why:

-

Products can pass AOI yet fail during functional testing

-

Boards pass factory inspection but fail at customer sites

-

Warranty and recall costs rise despite “good inspection results”

US buyers therefore view AOI as necessary but insufficient.

AOI vs Electrical vs Functional Testing: Different Roles, Different Risks

In-Circuit Test (ICT)

ICT verifies:

-

Shorts and opens

-

Component presence and values

-

Basic circuit integrity

ICT complements AOI by detecting electrical issues that are invisible to cameras. However, ICT does not confirm whether the board performs its intended function.

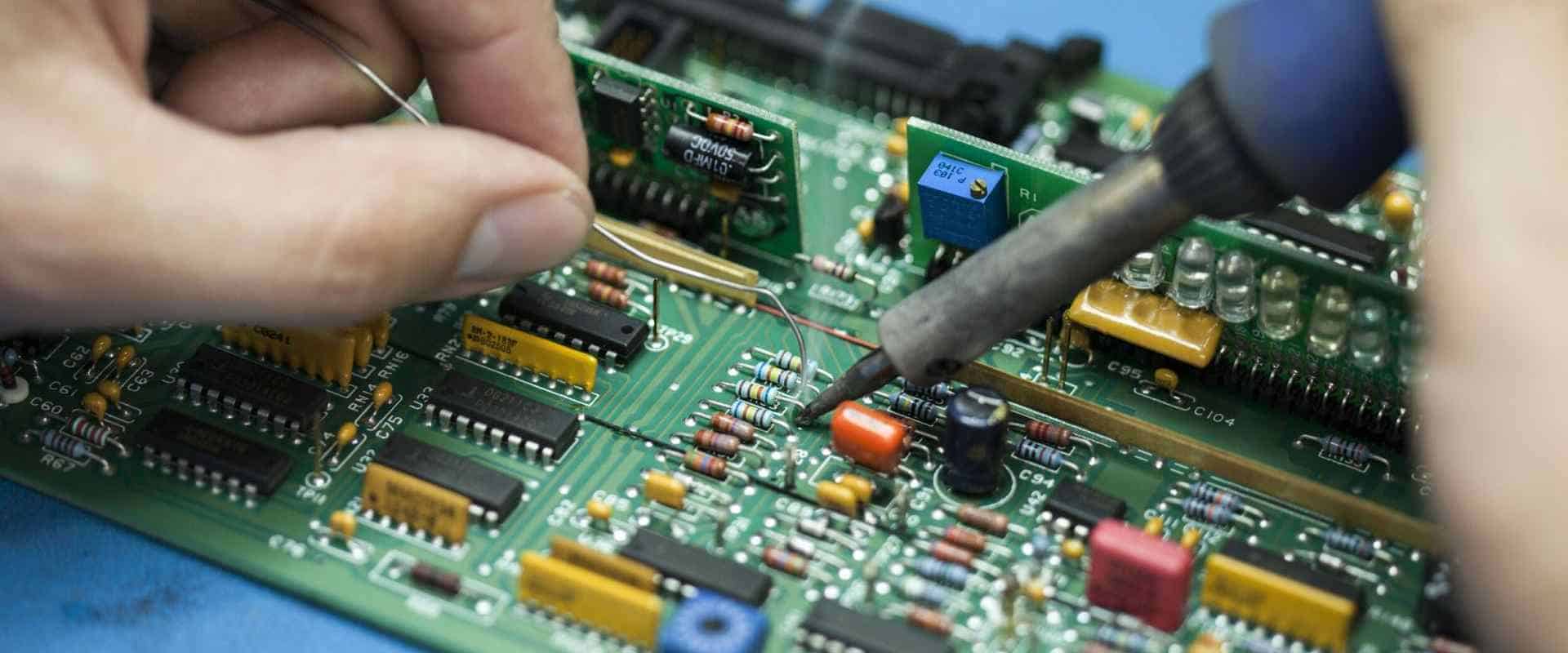

Functional Testing

Functional testing evaluates whether the PCBA operates correctly in real or simulated operating conditions.

Functional tests may include:

-

Power-up and shutdown behavior

-

Signal processing

-

Communication protocols

-

Response to inputs, sensors, or loads

For PCBA control boards, industrial equipment, office machines, and consumer electronics, functional testing is often the most important step in preventing field failures.

>>>Read more: PCBA Control Board Manufacturing Process: From Design to Production

Why PCBA Control Boards Require Deeper Testing

Control boards interact with:

-

Motors

-

Power supplies

-

Sensors

-

User interfaces

Failures in these boards can lead to:

-

System downtime

-

Safety risks

-

Costly service interventions

US companies therefore expect testing that goes beyond AOI and basic electrical checks. Functional and stress-oriented testing are often required to ensure stable long-term performance.

How US Companies Define “Enough” Testing

US companies do not define “enough testing” by the number of inspection machines.

Instead, they evaluate:

-

Application criticality

-

Cost of failure in the field

-

Regulatory or safety exposure

-

Product lifecycle and scale

For low-risk consumer products, AOI + basic functional testing may be sufficient.

For industrial, medical, or control applications, deeper testing is expected.

AOI is treated as a starting point, not a final quality gate.

AOI as Part of a Closed-Loop Quality System

AOI creates real value only when it is used as part of a feedback-driven system.

Leading manufacturers use AOI data to:

-

Identify defect patterns

-

Improve solder paste printing (SPI feedback)

-

Adjust placement and reflow profiles

-

Prevent recurrence of defects

The key distinction for US buyers is not whether AOI exists, but whether AOI data influences process decisions.

PCBA Testing at SHDC: From Inspection to Reliability

Founded in 2022, SHDC is one of the few Vietnamese companies pioneering PCBA manufacturing and assembly for printers, computers, office equipment, consumer electronics, and home appliances. Backed by an experienced management and engineering team with leadership backgrounds at global corporations, SHDC is focused on becoming a leading PCB assembly provider.

SHDC supports a wide range of PCB types, from small boards (50 × 50 mm) to large formats (460 × 550 mm), handling components from 0201 sizes up to 100 mm, including flexible FPCs for high-tech products. The company has participated in manufacturing PlugBug chargers sold at Apple Stores in the US and Europe, and previously produced computer mice for leading global brands, demonstrating its capability to deliver complete, export-ready electronic products.

At SHDC, AOI is integrated into a broader PCBA testing framework designed around product risk and application requirements.

SHDC’s testing approach typically includes:

-

AOI combined with upstream process controls

-

Electrical testing matched to board complexity

-

Functional testing based on real operating conditions

-

Clear documentation and traceability for each build

This system-level approach is particularly important for:

-

Control boards used in office equipment

-

Industrial and consumer electronics

-

Export-oriented products requiring consistent reliability

By aligning testing depth with product risk, SHDC supports stable quality, reduced field failures, and predictable long-term performance.

>>>Read more: Profle’s SHDC Company

Common Misconceptions About AOI in PCBA Testing

-

“AOI guarantees quality.”

AOI guarantees visual conformity, not reliability. -

“Functional testing is optional.”

For many applications, functional testing is essential. -

“More inspection equals better quality.”

Process control and decision-making matter more than inspection quantity.

FAQs

Is AOI required for all PCBA manufacturing?

AOI is not legally required, but it is widely expected by US buyers as a baseline quality measure.

Can AOI detect cold solder joints?

Not reliably. Cold joints often appear visually acceptable.

Why do boards fail after passing AOI and functional test?

Because latent defects may only appear after extended operation, temperature cycling, or load stress.

How do US companies decide testing depth?

By evaluating application risk, cost of failure, and long-term reliability requirements.

Final Thoughts: Is AOI Enough in PCBA Testing?

AOI is a critical tool—but it is not enough on its own. US companies evaluate PCBA testing as a risk management system, not an inspection checklist. Reliable products are the result of layered testing, disciplined process control, and data-driven decisions. Understanding the real role of AOI helps buyers choose manufacturing partners who focus not just on passing inspections, but on delivering consistent, long-term reliability.

Tiếng Việt

Tiếng Việt 日本語

日本語