A PCBA control board is the core functional unit in many electronic systems, responsible for power regulation, logic control, and system operation. For US companies outsourcing PCBA control board manufacturing, defects introduced during assembly often do not appear immediately, but emerge later as field failures, reliability issues, and warranty costs. Understanding how control boards are designed, assembled, and tested is essential for reducing manufacturing risk and ensuring long-term product performance.

What Is a PCBA Control Board?

A PCBA control board is a printed circuit board assembly designed to manage and control the operation of an electronic system. Unlike simple interface or sensor boards, control boards typically handle critical functions such as power management, motor control, logic processing, and communication between subsystems.

Common applications include:

-

Industrial automation and machinery

-

Home appliances and HVAC systems

-

Printers, copiers, and office equipment

-

Consumer electronics with embedded control functions

Control boards are often confused with main boards or logic boards. While there may be overlap, a control board is usually more function-specific, operating under higher electrical, thermal, or mechanical stress—making manufacturing quality especially important.

Design & Data Readiness for PCBA Control Boards

Many PCBA control board failures originate not on the production line, but during the design and data preparation phase.

BOM Accuracy and Component Selection

An incomplete or inaccurate bill of materials (BOM) is a common source of manufacturing risk. Typical issues include:

-

Missing manufacturer part numbers (MPNs)

-

No indication of component lifecycle status

-

Unapproved or undocumented component substitutions

For control boards, uncontrolled component changes can affect electrical performance, thermal behavior, and long-term reliability. US buyers should ensure BOMs clearly define approved alternates and lifecycle risks before production begins.

DFM & DFA Considerations for Control Boards

Design for Manufacturability (DFM) and Design for Assembly (DFA) are especially critical for control boards due to their functional complexity.

Key considerations include:

-

Pad design and solder mask definition

-

Adequate spacing for high-current and high-voltage areas

-

Thermal layout for heat-generating components

-

Mechanical reinforcement for connectors and relays

A thorough DFM/DFA review reduces assembly defects and improves yield stability during mass production.

Gerber, Pick & Place, and Revision Control

Version control issues remain a major red flag in outsourced PCBA projects. Common problems include:

-

Mismatched Gerber, BOM, and pick-and-place files

-

Engineering Change Notices (ECNs) not fully implemented

-

Multiple uncontrolled revisions in parallel production

Robust revision control is essential to ensure the correct control board design is built every time.

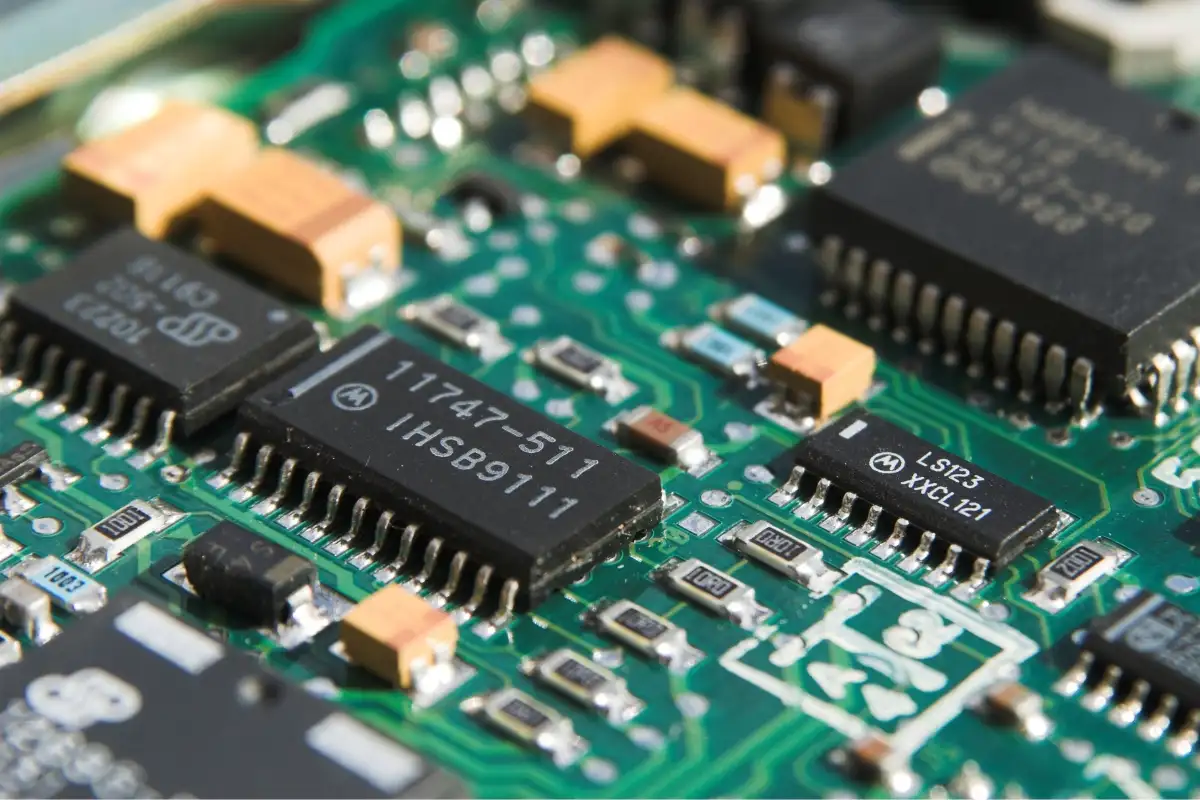

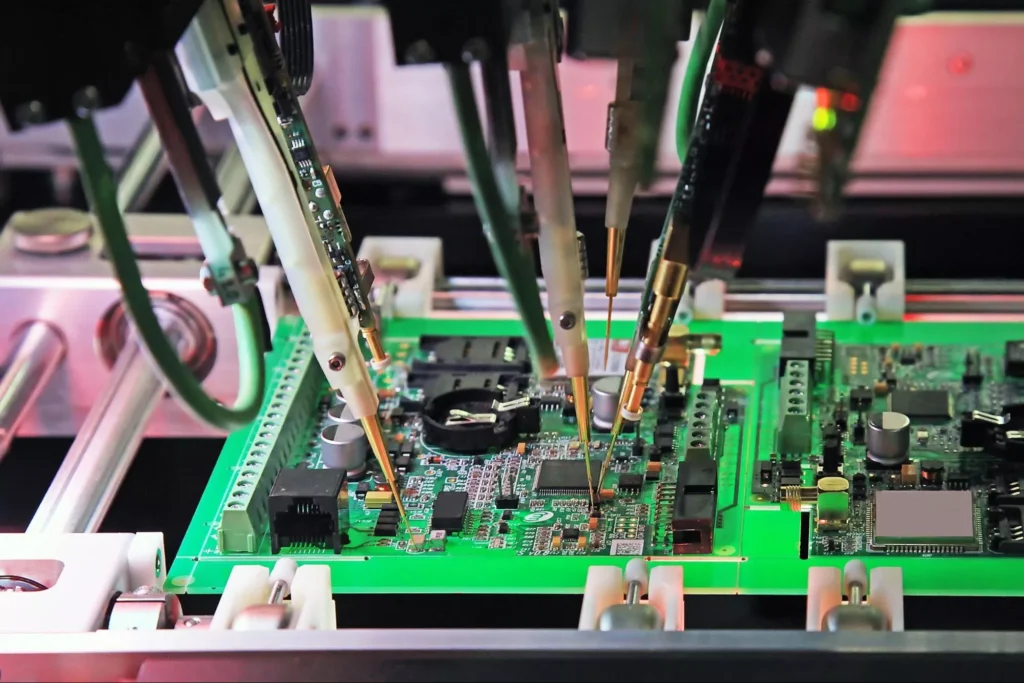

Critical Manufacturing Steps in PCBA Control Board Assembly

Solder Paste Printing and SPI Control

Solder paste printing is one of the most influential steps in PCBA control board manufacturing. Variations in paste thickness or aperture design can lead to insufficient solder joints or bridging defects.

Solder Paste Inspection (SPI) acts as an early indicator of process health, helping manufacturers detect yield issues before reflow soldering.

Pick & Place Accuracy and Component Handling

Control boards often use fine-pitch components such as BGAs and QFNs, as well as power devices sensitive to handling conditions.

Critical controls include:

-

High-accuracy placement for fine-pitch components

-

Proper storage and handling of moisture-sensitive devices (MSDs)

-

Strict ESD control throughout the assembly process

Failures in this stage may not be immediately visible but can significantly reduce product lifetime.

Reflow Soldering Profile Optimization

A well-optimized reflow profile ensures proper solder joint formation without damaging components.

For control boards, improper profiles can cause:

-

Cold solder joints

-

Tombstoning

-

Thermal stress on power components

Because control boards often operate under continuous electrical and thermal load, reflow stability directly impacts long-term reliability.

>>>Read more: PCBA Contract Manufacturing: What US Companies Should Know Before Outsourcing

Common Risks in PCBA Control Board Manufacturing

Electrical and Power-Related Failures

Power-related issues are among the most common field failures in control boards, including:

-

Voltage instability

-

Overheating

-

Failure under power cycling conditions

These issues often stem from subtle manufacturing variations rather than obvious defects.

Thermal and Mechanical Reliability Issues

Control boards frequently operate in environments with vibration, mechanical stress, or elevated temperatures.

Risks include:

-

Poor heat dissipation

-

Connector fatigue

-

Solder joint cracking under vibration

Manufacturing processes must account for these real-world conditions.

Process Variation and Yield Loss

Inconsistent process control can lead to batch-to-batch variation, where defects appear intermittently. These problems are difficult to diagnose and costly to resolve once products are in the field.

Testing and Reliability Considerations for Control Boards

AOI: What It Can and Cannot Detect

Automated Optical Inspection (AOI) is effective for identifying visible defects such as missing or misaligned components. However, AOI cannot verify electrical functionality or performance under load.

ICT for Electrical Validation

In-Circuit Testing (ICT) validates basic electrical integrity, including opens and shorts. While ICT requires fixture investment, it provides scalable electrical validation for volume production.

Functional Testing Under Real Conditions

Functional testing (FCT) is critical for PCBA control boards. Effective FCT evaluates:

-

Power-on behavior

-

Load and stress conditions

-

Firmware interaction and system response

Testing strategies should align with product risk rather than relying solely on visual inspection.

How to Choose a PCBA Partner for Control Board Manufacturing

When evaluating a PCBA control board manufacturing partner, US companies should focus on more than unit price.

Key evaluation factors include:

-

Process control and documentation (work instructions, SPC data)

-

Engineering support and DFM feedback

-

Communication speed and issue resolution

-

Scalability from prototype to mass production

A reliable partner treats PCBA manufacturing as a risk management process, not just an assembly task.

SHDC – A Pioneer in PCBA Control Board Manufacturing in Vietnam

Founded in 2022, SHDC is among the few Vietnamese companies that entered the PCBA manufacturing sector with a clear focus on high-quality electronic assembly. From the beginning, SHDC has specialized in printed circuit board assembly (PCBA), particularly for control boards used in printers, fax machines, computers, consumer electronics, and home appliances.

By concentrating on process discipline and quality-driven manufacturing, SHDC positions itself as a reliable PCBA control board manufacturing partner for both domestic and international customers, including projects serving the US market.

Company Foundation and Long-Term Manufacturing Vision

Although relatively young, SHDC was established with a long-term vision: to become one of Vietnam’s leading PCBA manufacturing companies capable of supporting export-oriented electronics production. Rather than competing purely on cost, SHDC focuses on building stable manufacturing processes, scalable capacity, and engineering-driven execution—key factors US companies look for when outsourcing PCBA control board production.

This strategic approach allows SHDC to support customers beyond prototype builds, extending into mass production and long-term product lifecycles.

Experienced Management and Engineering Leadership

One of SHDC’s strongest differentiators lies in its management and engineering leadership. The core team consists of professionals with extensive industry experience who have previously held senior technical and leadership roles at major global corporations.

This background enables SHDC to operate PCBA manufacturing processes that emphasize quality control, traceability, documentation, and compliance with international manufacturing standards. For US customers, this translates into better communication, clearer technical alignment, and reduced operational risk throughout the PCBA control board manufacturing process.

>>>Read more: SHDC – Company Profile

Comprehensive PCBA and Control Board Manufacturing Capabilities

From a technical perspective, SHDC offers flexible and comprehensive PCBA manufacturing capabilities designed to support a wide range of control board requirements:

-

PCB sizes ranging from 50 × 50 mm to 460 × 550 mm

-

Component assembly from 0201, 0402, 0603 packages up to 100 mm components

-

Support for both rigid PCBs and flexible printed circuits (FPCs)

These capabilities allow SHDC to manufacture PCBA control boards with varying complexity levels, from compact embedded control boards to larger boards used in industrial and consumer electronic systems.

Experience Manufacturing Control Boards for Complex Electronic Products

Control boards often serve as the “brain” of electronic products, directly impacting system stability, safety, and long-term reliability. SHDC has accumulated hands-on experience assembling control boards used in devices such as printers, computing peripherals, and consumer electronics, where electrical performance and consistency are critical.

Through disciplined PCBA manufacturing processes and engineering oversight, SHDC helps customers reduce risks related to soldering defects, component failures, and long-term field reliability—issues that US buyers are especially concerned about when outsourcing control board production.

Participation in High-Quality, Export-Oriented Electronics Projects

SHDC has demonstrated its ability to meet the demands of export-oriented electronics manufacturing. A notable example is its participation in the production stages of PlugBug, a charger product distributed through Apple retail stores in the United States and Europe.

This project required strict adherence to quality, process control, and compliance expectations, reinforcing SHDC’s capability to support PCBA control board manufacturing for internationally distributed products. Prior to PlugBug, SHDC also assembled computer peripherals for leading global brands, further strengthening its credibility in quality-focused PCBA manufacturing.

Beyond Assembly: End-to-End Electronic Manufacturing Capability

Unlike many local suppliers that focus only on packaging, plastics, mechanical parts, or individual components, SHDC is among the few companies in Vietnam capable of delivering complete electronic products for export.

This end-to-end capability allows SHDC to support customers not only with PCBA control board assembly, but also with broader manufacturing coordination, consistency, and scalability—key requirements for US companies seeking long-term manufacturing partners rather than short-term vendors.

A Reliable PCBA Control Board Manufacturing Partner for Global Markets

By combining experienced leadership, disciplined processes, and comprehensive PCBA manufacturing capabilities, SHDC positions itself as a reliable partner for companies sourcing PCBA control boards for global markets.

For US buyers evaluating offshore PCBA manufacturing options, SHDC offers a balanced approach: competitive manufacturing in Vietnam, supported by process transparency, engineering expertise, and a strong commitment to quality and long-term collaboration.

Final Thoughts

A PCBA control board is not a simple electronic assembly. Its reliability depends heavily on design readiness, manufacturing discipline, and test strategy.

For US companies outsourcing production, selecting the right PCBA manufacturing partner is a strategic decision—one that directly affects product performance, cost, and long-term success.

Tiếng Việt

Tiếng Việt 日本語

日本語