Modern electronics demand smaller, faster, and more reliable circuit boards. To meet these requirements, manufacturers rely on SMT manufacturing, the industry-standard method for assembling electronic components onto PCBs. In this article, we explain what SMT manufacturing is, how it works, and why it plays a critical role in today’s electronics production and supply chains.

How SMT Manufacturing Works in Electronics Production

What is SMT Manufacturing Process

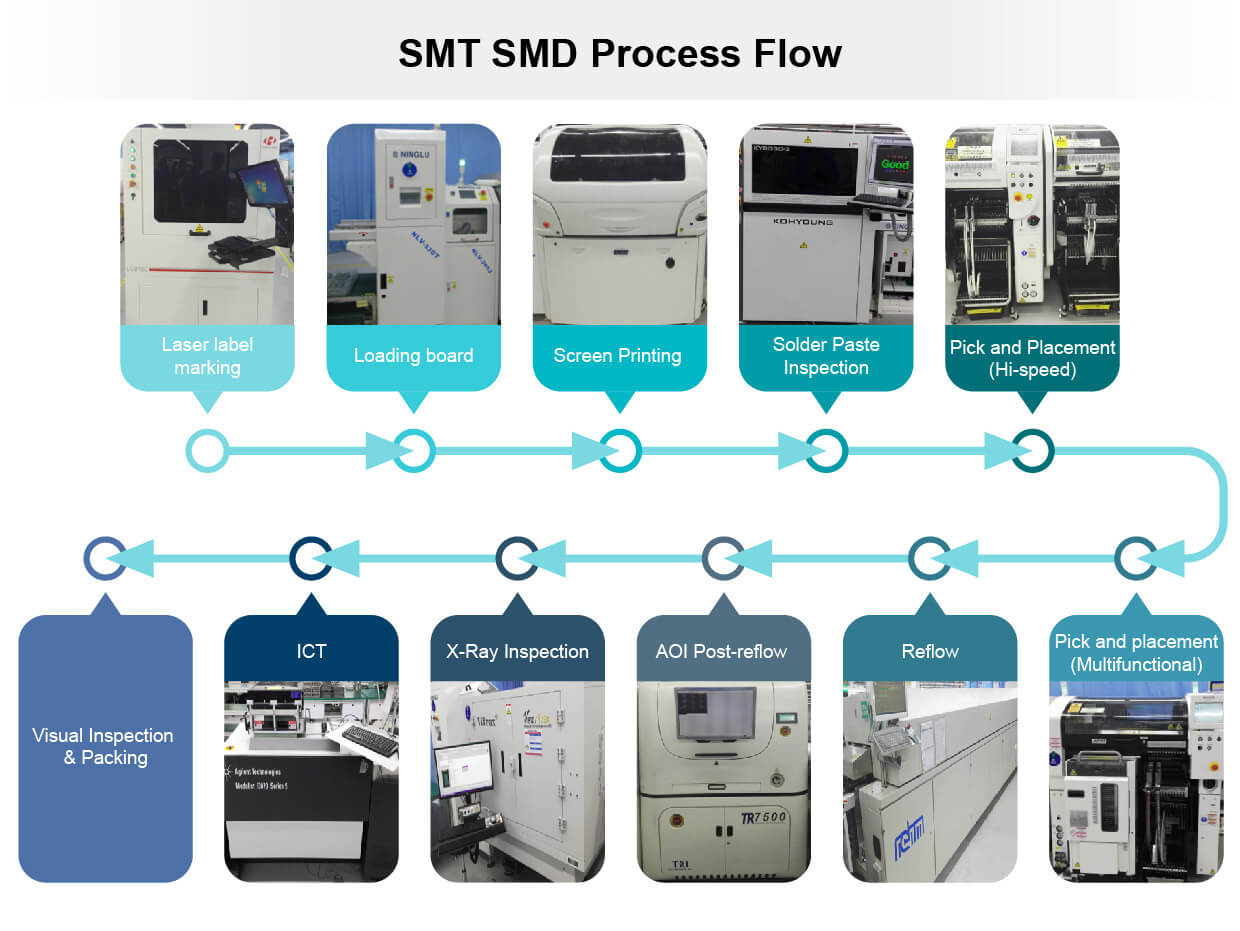

The SMT manufacturing process follows a well-defined workflow designed for accuracy, efficiency, and scalability. While specific setups may vary by factory, the core process typically includes the following steps:

1. Solder Paste Printing

Solder paste is applied to the PCB pads using a stencil. This step ensures proper solder volume and alignment before component placement.

2. Pick-and-Place Assembly

Automated pick-and-place machines position surface mount components onto the PCB with high speed and precision.

3. Reflow Soldering

The assembled board passes through a reflow oven, where controlled heat melts the solder paste and creates reliable electrical and mechanical connections.

4. Inspection and Testing

nspection systems such as SPI (Solder Paste Inspection) and AOI (Automated Optical Inspection) verify solder quality, component placement, and assembly accuracy.

This structured process allows SMT manufacturing lines to achieve high throughput with minimal human intervention.

Key Equipment Used in SMT Manufacturing

SMT manufacturing depends on specialized equipment designed for automation and consistency. Common machines include:

-

Solder paste printers

-

High-speed pick-and-place machines

-

Reflow ovens

-

SPI and AOI inspection systems

For electronics buyers in the US, the type, brand, and configuration of SMT equipment are often key indicators of a manufacturer’s technical capability and production reliability.

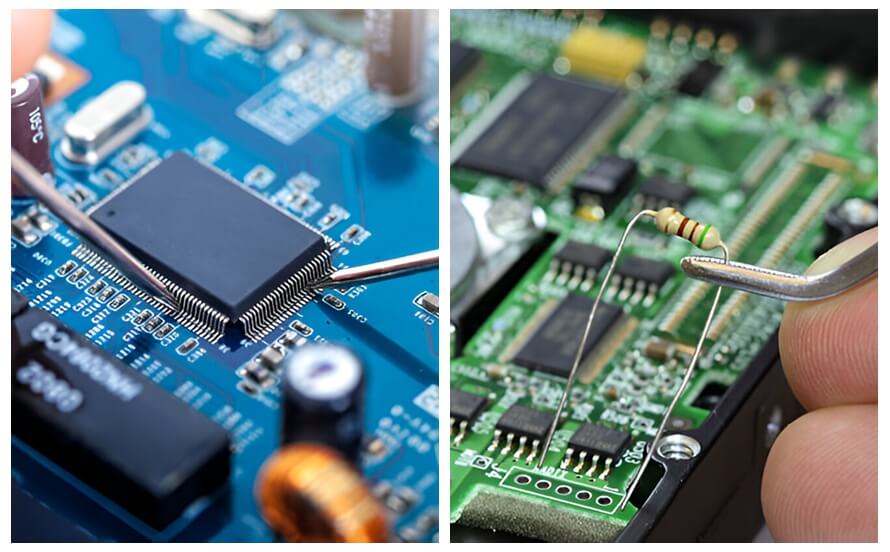

SMT Manufacturing vs Through-Hole Manufacturing

SMT manufacturing enables smaller board sizes, higher component density, and faster production speeds. It is highly compatible with automation, which improves yield rates and reduces labor dependency. Through-hole manufacturing, by contrast, is slower, more labor-intensive, and better suited only for components that require strong mechanical anchoring.

For most commercial and industrial electronics, SMT manufacturing offers clear advantages in cost efficiency, scalability, and design flexibility.

Why SMT Manufacturing Matters in Modern Electronics

Miniaturization and High-Density PCB Design

As electronic products continue to shrink in size while increasing in functionality, SMT manufacturing makes high-density PCB designs possible. Surface mount components are smaller and can be placed on both sides of the board, enabling compact layouts that would be impractical with through-hole technology.

This capability is especially important for applications such as wearable devices, medical electronics, and advanced control systems.

Automation, Scalability, and Cost Control

SMT manufacturing is inherently automation-friendly. Automated lines reduce human error, improve consistency, and support both low-volume and high-volume production.

For OEMs and startups alike, this scalability allows products to move smoothly from prototyping to mass production without major process changes. Automation also helps control costs by improving yield and reducing rework.

Impact on Product Reliability and Performance

A well-controlled SMT manufacturing process contributes directly to product reliability. Proper solder joints, accurate placement, and consistent thermal profiles improve signal integrity and reduce long-term failure risks.

For electronics buyers, this translates into fewer field failures, lower warranty costs, and better overall product performance.

Applications of SMT Manufacturing Across Industries

SMT manufacturing is used across a wide range of industries, including:

-

Consumer electronics such as smartphones, wearables, and smart home devices

-

Industrial electronics including control boards, sensors, and automation systems

-

Medical devices where precision and reliability are critical

-

Automotive electronics such as control modules and safety systems

This broad adoption highlights the flexibility and robustness of SMT manufacturing as a production method.

SMT Manufacturing and PCBA: How They Work Together

SMT manufacturing is a core part of the PCBA process. While PCBA includes multiple steps such as component sourcing, assembly, inspection, and testing, SMT is the primary method used to mount components onto the PCB.

The quality of SMT manufacturing directly affects PCBA performance. Poor solder paste control, inaccurate placement, or insufficient inspection can lead to defects that compromise the entire assembly. As a result, experienced manufacturers place strong emphasis on SMT process control within their overall PCBA operations.

What to Look for in an SMT Manufacturing Partner

Choosing the right SMT manufacturing partner is a strategic decision for electronics buyers.

SMT Line Capability and Equipment

Evaluate the supplier’s SMT line configuration, including machine capability, automation level, and capacity. A well-equipped SMT line indicates readiness for both current and future production needs.

Quality Control and Process Management

Effective SMT manufacturing relies on robust quality systems. Look for manufacturers that implement SPI, AOI, and traceability systems, and that follow recognized standards such as IPC guidelines.

Engineering Support and Communication

Strong engineering support is especially important during new product introduction (NPI). Manufacturers that offer DFM feedback, process optimization, and clear communication can significantly reduce production risks and delays.

SMT Manufacturing in Global Supply Chains

Why US Companies Are Rethinking SMT Sourcing

Many US companies are reassessing their electronics manufacturing strategies in response to cost pressures, supply chain disruptions, and geopolitical uncertainty. As a result, sourcing decisions increasingly focus on resilience, transparency, and long-term stability rather than cost alone.

SMT Manufacturing in Vietnam: An Emerging Alternative

Vietnam has emerged as a competitive location for SMT manufacturing, offering a balance of cost efficiency, skilled labor, and a rapidly improving manufacturing infrastructure. For US companies seeking to diversify their supply chains, Vietnam presents a practical alternative for SMT assembly and PCBA production without sacrificing quality or process control.

Among local manufacturers, SHDC stands out as a specialized SMT and PCBA partner supporting international customers. With modern SMT production lines, experienced engineering teams, and a strong focus on process control and quality assurance, SHDC helps US companies transition SMT manufacturing to Vietnam with minimal risk. The company’s capabilities span from prototype and low-volume builds to scalable production, enabling OEMs and product teams to maintain consistency as volumes grow.

By combining Vietnam’s manufacturing advantages with structured communication, engineering support, and quality-driven SMT processes, SHDC positions itself as a reliable option for US companies looking to build more resilient and diversified electronics supply chains.

Final Thoughts: Why SMT Manufacturing Is a Strategic Advantage

SMT manufacturing is more than a technical process—it is a strategic enabler of modern electronics production. By supporting miniaturization, automation, and scalable manufacturing, SMT allows companies to bring reliable products to market faster and more efficiently.

For electronics buyers and OEMs, understanding SMT manufacturing is essential to evaluating suppliers, managing risk, and building resilient supply chains. Choosing the right SMT manufacturing partner can make a measurable difference in product quality, cost control, and long-term success.

Tiếng Việt

Tiếng Việt 日本語

日本語