Printed circuit board assembly (PCBA) is one of the most critical and risk-sensitive stages in electronics manufacturing. Defects introduced during the printed circuit board assembly process can directly impact product reliability, functional performance, and long-term cost—even when PCB design and components meet specifications.

For US companies outsourcing printed circuit board assembly (PCBA), many quality issues do not appear during visual inspection or initial testing. Instead, they surface later in real-world use, leading to field failures, warranty claims, and costly rework. Understanding common PCBA defects and their root causes is essential for reducing manufacturing risk and selecting the right PCBA partner.

Soldering Defects in Printed Circuit Board Assembly (PCBA)

Solder joints provide both the electrical and mechanical foundation of every assembled circuit board. In printed circuit board assembly (PCBA), even small variations in soldering quality can significantly reduce long-term reliability.

Insufficient or Excess Solder

Insufficient solder reduces electrical contact area, while excess solder increases the risk of bridging and mechanical stress.

Common root causes in PCBA manufacturing include:

-

Inconsistent solder paste thickness

-

Improper stencil aperture design

-

Poor solder paste printing control

Impact on printed circuit board assembly quality:

-

Intermittent electrical connections

-

Latent defects that pass initial inspection but fail in the field

Solder Bridging

Solder bridging occurs when solder unintentionally connects adjacent pads or leads, particularly in high-density PCB assembly designs using QFN or BGA components.

Typical causes:

-

Pad spacing not optimized for fine-pitch components

-

Excess solder paste deposition

-

Pick-and-place accuracy limitations

Business risk for US companies:

-

Immediate short circuits

-

Increased rework cost

-

Delays in product launch schedules

Cold or Weak Solder Joints

Cold solder joints are among the most dangerous printed circuit board assembly defects because they are difficult to detect visually or through AOI.

Primary causes:

-

Reflow profiles outside the component thermal window

-

Insufficient soak or peak temperature duration

Consequences:

-

Reduced mechanical strength

-

Field failures under vibration, shock, or thermal cycling

>>>Read more: PCBA and PCB: A detailed technical comparison of printed circuit boards and assemblies

Component Placement Errors in Printed Circuit Board Assembly

Component Misalignment

Misaligned components may still pass automated inspection but weaken solder joints in PCBA manufacturing.

Contributing factors:

-

Inadequate pick-and-place calibration

-

Excessive line speed

-

PCB warpage or poor panelization design

Impact:

-

Reduced mechanical reliability

-

Higher risk during shipping and long-term use

Polarity and Orientation Errors

Polarity errors are especially critical for diodes, polarized capacitors, power ICs, and sensors in printed circuit board assembly (PCBA).

Root causes:

-

Incomplete BOM polarity information

-

Pick-and-place data mismatches

-

Poorly controlled engineering change notices (ECNs)

Risk exposure:

-

Immediate failure at power-on

-

Potential damage to surrounding circuitry

Missing or Incorrect Components

Missing or incorrect components often indicate weaknesses in material control and traceability within the PCBA process.

Business impact:

-

Increased rework and scrap

-

Loss of lot-level quality visibility

-

Difficulty performing root-cause analysis after field failures

Component and Material Risks in PCBA Manufacturing

Non-Compliant or Unverified Components

For US buyers, component authenticity and compliance are critical aspects of printed circuit board assembly.

Risks include:

-

Incorrect electrical performance

-

Reduced component lifespan

-

Non-compliance with standards such as RoHS or UL

Improper Handling of Moisture-Sensitive Devices (MSDs)

MSDs require strict storage, baking, and floor-life control during printed circuit board assembly (PCBA).

When mishandled:

-

“Popcorn effect” during reflow

-

Internal package cracking

-

Latent failures appearing months after deployment

Testing Gaps in the Printed Circuit Board Assembly Process

Over-Reliance on AOI

AOI identifies visual defects but does not validate electrical performance or real-world functionality in PCBA manufacturing.

AOI alone cannot detect:

-

Open or intermittent connections

-

Firmware-related or power-on failures

Lack of ICT or Functional Testing (FCT)

Skipping electrical or functional testing significantly increases downstream risk.

For US companies, this often results in:

-

Higher RMA rates

-

Increased warranty and support costs

-

Reputational damage

In most cases, the cost of testing during printed circuit board assembly is far lower than the cost of resolving failures after shipment.

Process and Change Management Risks in PCBA Contract Manufacturing

Poor ECN Control

Uncontrolled changes to components, footprints, or assembly processes frequently lead to:

-

Version mismatches

-

Repeated defects that are difficult to trace

Strong ECN discipline is a core requirement for reliable printed circuit board assembly contract manufacturing.

Lack of Traceability

Component-level and board-level traceability are essential for many US industries, including industrial, automotive, and medical electronics.

Without traceability in the PCBA manufacturing process:

-

Audits become difficult

-

Product recalls carry higher risk

-

Customer confidence is reduced

>>>Read more: PCBA Contract Manufacturing: What US Companies Should Know Before Outsourcing

How US Companies Reduce Printed Circuit Board Assembly Defects

Design for Manufacturability and Assembly (DFM/DFA)

Early DFM/DFA reviews help:

-

Reduce soldering and placement risks

-

Improve test access

-

Stabilize yields when scaling production volume

Data-Driven Process Control

High-quality printed circuit board assembly (PCBA) relies on measurable performance indicators such as:

-

First Pass Yield (FPY)

-

Statistical Process Control (SPC)

-

Defect trend analysis by process stage

Selecting the Right Printed Circuit Board Assembly Partner

A capable printed circuit board assembly contract manufacturer does more than assemble boards. Key indicators include:

-

Documented and controlled assembly processes

-

Risk-based testing strategies

-

Engineering support from prototype through mass production

For US companies, partner selection should prioritize process maturity and long-term reliability, not just quoted price.

SHDC – Experienced Management and Engineering Leadership

A key differentiator of SHDC lies in its management and engineering leadership team. Team members bring extensive industry experience and have previously held senior technical and leadership roles at major global electronics corporations.

This background enables SHDC to operate PCBA manufacturing processes with a strong emphasis on:

-

Process discipline and standardization

-

Quality control and traceability

-

Compliance with international manufacturing and quality standards

These capabilities are essential for PCBA contract manufacturing projects serving US and global customers, where reliability, repeatability, and transparency are critical.

>>>Read more: SHDC Company Profile

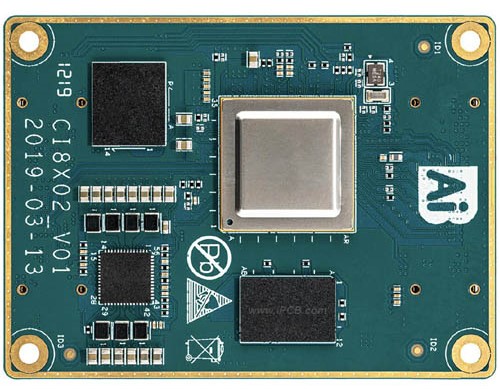

Comprehensive PCBA Manufacturing Capabilities

From a technical standpoint, SHDC supports a broad range of printed circuit board assembly (PCBA) requirements, including:

-

PCB sizes ranging from 50 × 50 mm to 460 × 550 mm

-

Component sizes from 0201, 0402, 0603 up to 100 mm

-

Assembly of both rigid PCBs and flexible printed circuits (FPCs)

These capabilities allow SHDC to support products of varying complexity—from compact consumer devices to larger, more complex electronic systems.

Participation in Export-Oriented, High-Quality Electronics Projects

SHDC has demonstrated its ability to support export-oriented electronics manufacturing programs with demanding quality and compliance requirements.

Notably, the company has participated in production stages of PlugBug, a charger product distributed through Apple retail stores in the US and Europe. This project reflects SHDC’s ability to meet stringent international standards related to quality, process control, and manufacturing consistency.

Prior to PlugBug, SHDC also assembled computer peripherals for leading global brands, further reinforcing its experience in quality-driven PCBA contract manufacturing.

End-to-End Electronic Manufacturing for Global Markets

Unlike many local suppliers that focus only on packaging, plastics, mechanical parts, or individual components, SHDC is among the few companies in Vietnam capable of delivering complete electronic products for export.

This end-to-end capability positions SHDC as a reliable PCBA contract manufacturing partner for companies seeking more than basic assembly—supporting requirements for consistency, scalability, and long-term manufacturing collaboration.

Conclusion

Most defects in printed circuit board assembly (PCBA) are not random events. They result from insufficient process control, weak change management, and inadequate testing strategies within the PCBA manufacturing process.

For US companies outsourcing electronics production, understanding common printed circuit board assembly defects enables better supplier evaluation, lower long-term cost, and improved product reliability. In this context, printed circuit board assembly contract manufacturing should be treated as a strategic decision—where risk control and process discipline matter more than short-term cost savings.

FAQs

What is printed circuit board assembly (PCBA)?

Printed circuit board assembly (PCBA) is the process of mounting and soldering electronic components onto a printed circuit board (PCB) to create a functional electronic assembly.

What are the most common printed circuit board assembly defects?

Common PCBA defects include solder bridging, cold solder joints, component misalignment, polarity errors, missing components, and insufficient testing coverage.

Why do PCBA defects often appear after products ship?

Many printed circuit board assembly defects are latent issues caused by weak solder joints, poor process control, or inadequate testing. These defects may pass initial inspection but fail under real-world conditions.

Is AOI enough to ensure printed circuit board assembly quality?

No. AOI only detects visual defects. Reliable printed circuit board assembly requires electrical testing (ICT) and functional testing (FCT) to verify performance.

How can US companies reduce risk when outsourcing printed circuit board assembly?

US companies can reduce risk by selecting PCBA partners with strong process control, traceability, documented ECN management, and risk-based testing strategies.

Tiếng Việt

Tiếng Việt 日本語

日本語